When most people think about workplace safety, they probably picture hard hats, safety goggles, and those bright yellow vests that make everyone look like a walking traffic cone. But there's another hero working quietly in the background of industrial facilities worldwide: explosion-proof cameras. These aren't your average security cameras—they're specially engineered guardians designed to keep watch in environments where a single spark could turn a regular Tuesday into front-page news.

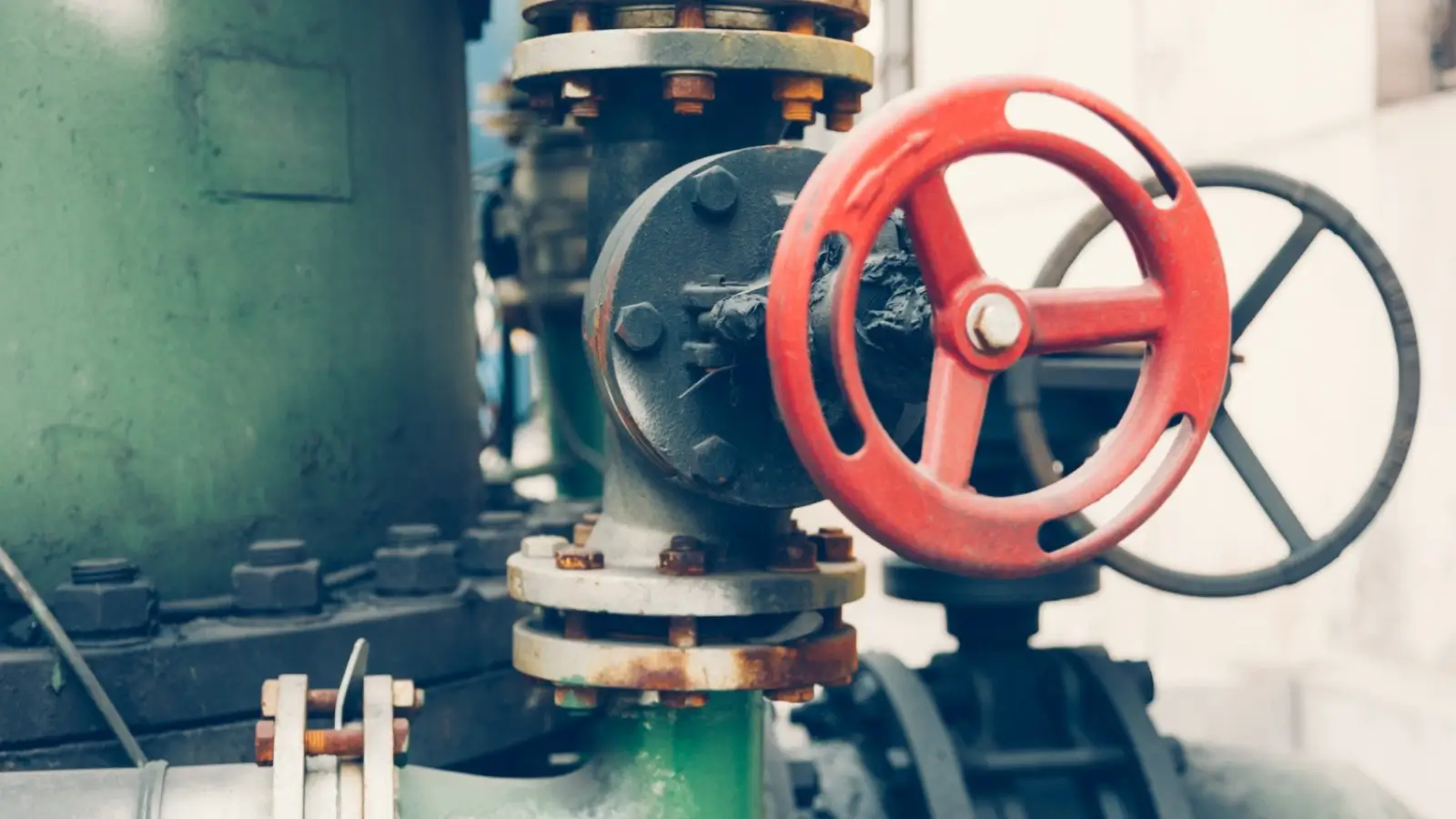

Industrial facilities face unique challenges that most office workers can't even imagine. One moment you're monitoring a routine process, and the next, you're dealing with volatile gases, combustible dust, or chemical vapors that could ignite faster than you can say "workplace incident report." This is where explosion-proof cameras step in, providing crucial monitoring capabilities without adding to the risk equation.

The importance of proper surveillance in hazardous environments cannot be overstated. These specialized cameras serve as our eyes and ears in places where human presence might be limited or dangerous, helping facility managers make informed decisions about safety protocols and emergency response.

What Makes a Camera Explosion-Proof?

The term "explosion-proof" might sound like something from an action movie, but it's actually a precise engineering specification. These cameras aren't designed to survive explosions—that would be asking a bit much from any piece of equipment. Instead, they're built to prevent explosions from occurring in the first place.

Explosion-proof cameras are housed in specially designed enclosures that can contain any internal sparks or heat generated by the camera's electrical components. Think of it as a really tough protective shell that keeps the dangerous stuff inside and the combustible atmosphere outside. The enclosure is built to withstand the pressure of an internal explosion and prevent it from igniting the surrounding hazardous atmosphere.

Key features of explosion-proof camera enclosures include:

-

Heavy-duty materials like cast aluminum or stainless steel

-

Specialized sealing systems to prevent gas penetration

-

Flame-resistant glass viewing windows

-

Carefully designed ventilation systems

-

Rigorous testing and certification processes

The engineering behind these cameras is quite remarkable. Every component must be carefully selected and tested to ensure it won't become an ignition source. Even something as simple as a loose screw could potentially create a spark, so manufacturers pay attention to details that would make your average perfectionist proud.

Industrial Applications That Depend on Safe Monitoring

Oil and gas facilities represent some of the most obvious applications for cameras designed for hazardous locations. These environments are filled with flammable vapors and gases that create a constant need for vigilant monitoring. Refineries, drilling platforms, and storage facilities all rely on these specialized cameras to maintain situational awareness without compromising safety.

Chemical processing plants face similar challenges but with their own unique twist. Here, the hazards might include corrosive substances, toxic gases, or materials that become unstable under certain conditions. Regular cameras would quickly succumb to the harsh environment, but explosion-proof models are built to handle these challenging conditions while continuing to provide clear video surveillance.

Manufacturing facilities that handle combustible materials also benefit greatly from proper surveillance systems. Grain elevators, for instance, might seem relatively benign, but grain dust can be surprisingly explosive under the right conditions. Wood processing plants, textile mills, and pharmaceutical manufacturing facilities all present their own unique monitoring challenges.

Mining operations present another category of hazardous environments where specialized surveillance equipment proves invaluable. Underground mines, in particular, can accumulate dangerous gases like methane, creating conditions where standard electrical equipment could trigger catastrophic events.

The Technology Behind the Safety

Modern explosion-proof cameras incorporate sophisticated technology while maintaining their safety credentials. High-definition video quality is now standard, ensuring that operators can see critical details even in challenging industrial environments. Many models include features like infrared capability for night vision, pan-tilt-zoom functionality for comprehensive coverage, and weather resistance for outdoor installations.

The integration capabilities of these cameras have also evolved significantly. They can connect to broader facility management systems, providing real-time data and alerts that help operators respond quickly to developing situations. Some advanced models even include analytics capabilities that can detect unusual movement patterns or environmental changes.

Wireless connectivity has become increasingly important, though it requires careful implementation in hazardous environments. The ability to transmit video data without running cables through potentially dangerous areas offers significant advantages for both installation and maintenance.

Regulatory Standards and Compliance

The world of industrial safety is heavily regulated, and cameras for hazardous locations must meet stringent standards before they can be deployed. Organizations like the National Electrical Manufacturers Association (NEMA) and Underwriters Laboratories (UL) provide testing and certification services that ensure equipment meets safety requirements.

Different hazardous location classifications require specific types of equipment:

-

Class I locations involve flammable gases or vapors

-

Class II locations feature combustible dust

-

Class III locations contain easily ignitable fibers

Each classification has multiple subdivisions based on the likelihood of hazardous materials being present, and cameras must be appropriately rated for their intended environment. Getting this wrong isn't just a matter of equipment failure—it could result in serious safety incidents and regulatory violations.

Installation and Maintenance Considerations

Installing cameras in hazardous locations requires specialized knowledge and often certified technicians. The installation process involves more than just mounting a camera and running cables. Every connection point must be properly sealed, and all electrical work must comply with strict safety standards.

Maintenance presents its own set of challenges. Routine cleaning and inspection must be performed without compromising the camera's safety features. This often requires specialized procedures and sometimes temporary shutdown of equipment or processes.

The good news is that modern explosion-proof cameras are designed for reliability and longevity. While they might cost more upfront than standard surveillance equipment, their durability in harsh environments often makes them more economical in the long run.

Making the Right Investment in Safety

Industrial facilities that cut corners on safety equipment often find that the savings aren't worth the risk. Explosion-proof cameras represent a proactive investment in facility safety that can pay dividends in multiple ways. Beyond the obvious safety benefits, they can help with regulatory compliance, insurance requirements, and overall operational efficiency.

The technology continues to evolve, with manufacturers regularly introducing new features and improvements. What hasn't changed is the fundamental importance of having reliable monitoring capabilities in hazardous industrial environments.

Choosing the right surveillance solution for hazardous locations requires careful consideration of specific environmental conditions, regulatory requirements, and operational needs. While the initial investment might seem substantial, the peace of mind and safety benefits make explosion-proof cameras an essential component of modern industrial safety programs.