Today’s consumers expect more from packaging—speedy delivery, fresh products, and visual appeal, all in one. For brands juggling efficiency, shelf presentation, and protection, flow wrapping offers one of the most streamlined solutions available. This flexible packaging format is ideal for a wide variety of product categories, from baked goods and bars to medical supplies and single-serve items.

At a time when speed to market and brand image can make or break a launch, flow wrap offers a practical edge for companies looking to scale quickly without compromising quality.

Key Benefits: Speed, Protection, and Shelf Appeal

1. Fast, high-volume production

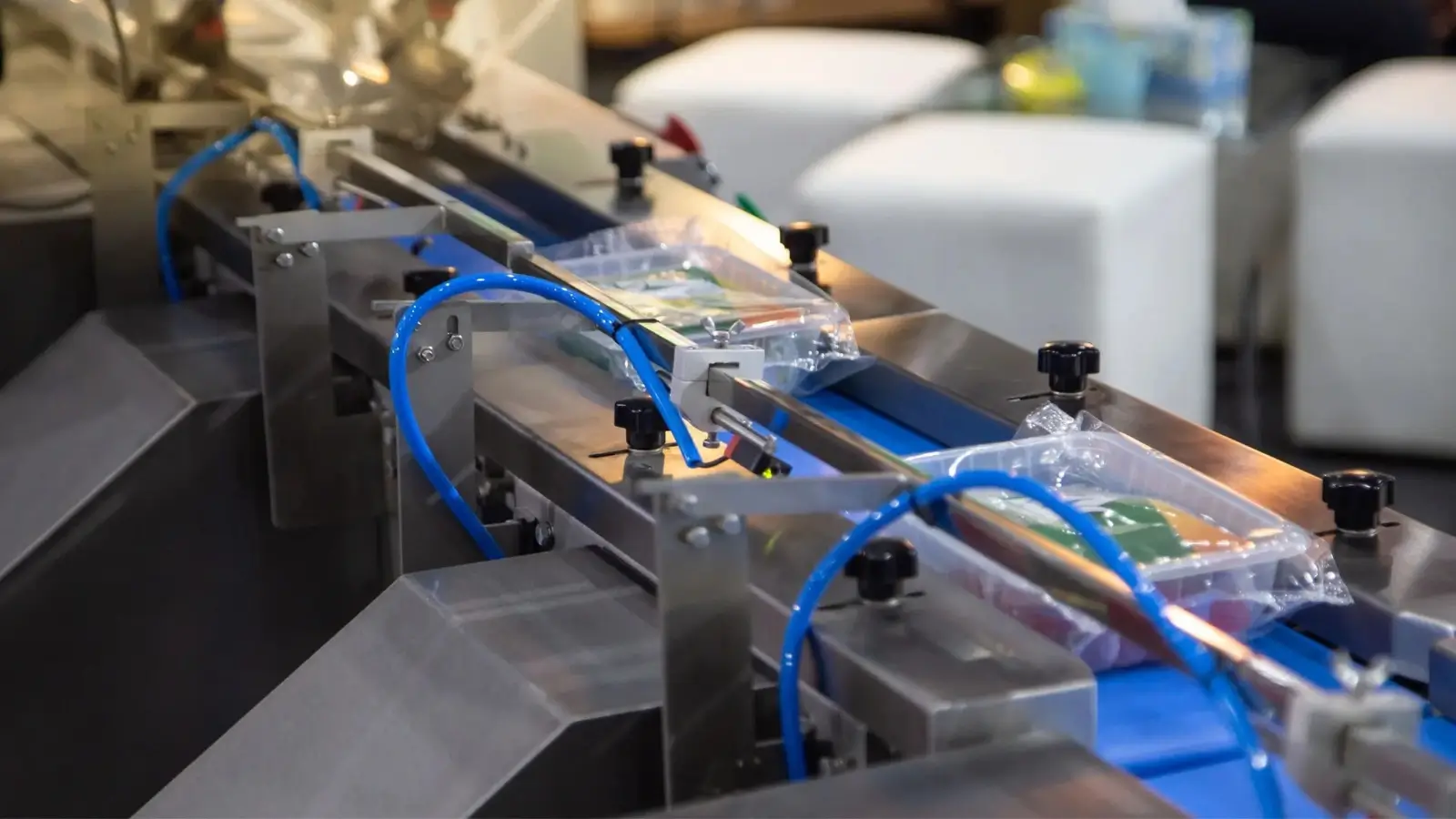

Flow wrap machines are built for speed. They wrap products continuously using a horizontal form-fill-seal process, sealing the film tightly around each item in seconds. This makes it one of the most efficient methods for high-throughput operations—ideal for snacks, personal care items, or small-format multipacks.

2. Barrier protection that keeps products fresh

Flow wrap can be made with high-barrier films to guard against moisture, oxygen, and light—ensuring extended shelf life and minimal waste. Whether you're packaging baked goods, supplements, or sensitive items like electronics, flow wrap can preserve freshness and functionality until it reaches the consumer.

3. Compact, sleek appearance

Flow-wrapped products look modern, clean, and uniform. With tight seals and minimal excess material, this format presents well on shelves and in eCommerce unboxing experiences. It’s an efficient way to show off bold branding and design without bulky materials.

4. Customizable and scalable

With digital printing, you can produce custom designs with variable data, promotional content, or seasonal graphics without traditional plate costs. Whether you’re testing a new flavor or running a limited-time offer, flow wrapping gives you the flexibility to pivot fast.

Comparing Flow Wrapping to Overwrapping and Other Methods

When selecting a packaging method, it’s important to weigh efficiency, consumer experience, and production cost. Flow wrap holds several key advantages over traditional overwrapping and rigid formats:

Versus Overwrapping:

Overwrapping involves folding and sealing a film around the product—think of how boxed tea or DVDs are wrapped. It often requires more steps, more material, and doesn’t provide the same tight seal as flow wrapping. For fast-paced environments, flow wrap reduces material waste and boosts output.

Versus Pouches and Bags:

While flexible bags—like mylar packaging—offer excellent protection and resealability, they may not be necessary for single-use or pre-portioned products. Flow wrap excels for items that don’t require zippers or child resistance but still need reliable protection.

That said, brands that require regulated protection can still opt for child resistant bags, which combine safety with flexible design. It’s all about matching the packaging to the use case.

Flow wrapping isn’t a one-size-fits-all solution—but when applied strategically, it delivers unmatched speed, sleekness, and savings. For growing brands, it's an opportunity to improve operational efficiency while elevating the customer experience from the first glance.