As smart manufacturing sweeps across factories worldwide, production processes are being held to fresh standards, and that is especially true in fields demanding tight tolerances. For precision machining parts manufacturers, the trend brings pressure but also a doorway to growth. Leading the charge are CNC turned parts shops, which now reinvent workflows, machines, and culture so they can keep pace with the speed, flexibility, and relentless appetite for data that smart factories expect.

In the pages that follow, we will look at the practical steps these companies are taking-leaning on intelligent automation, watching metrics in real time, and opening design to wider teams-so they stay relevant in a supply chain driven by information instead of guesswork.

What Being Part of a Smart Factory Means for CNC Production

A smart factory is more than a room full of robots; it is a living network where machines, software, and people exchange information continuously. For any CNC turned parts manufacturers,hoping to plug into such an environment, three characteristics stand out as goals to chase:

-

Data-driven decision-making: Every tool should track its own uptime and alert staff when a cut drifts out of spec.

-

Interconnectivity: CNC lathes must talk to ERP systems, cloud dashboards, and even the kiosk at the front desk.

-

Agility: Setups should shift quickly so customers get personalized runs without paying for long lead times or excess stock.

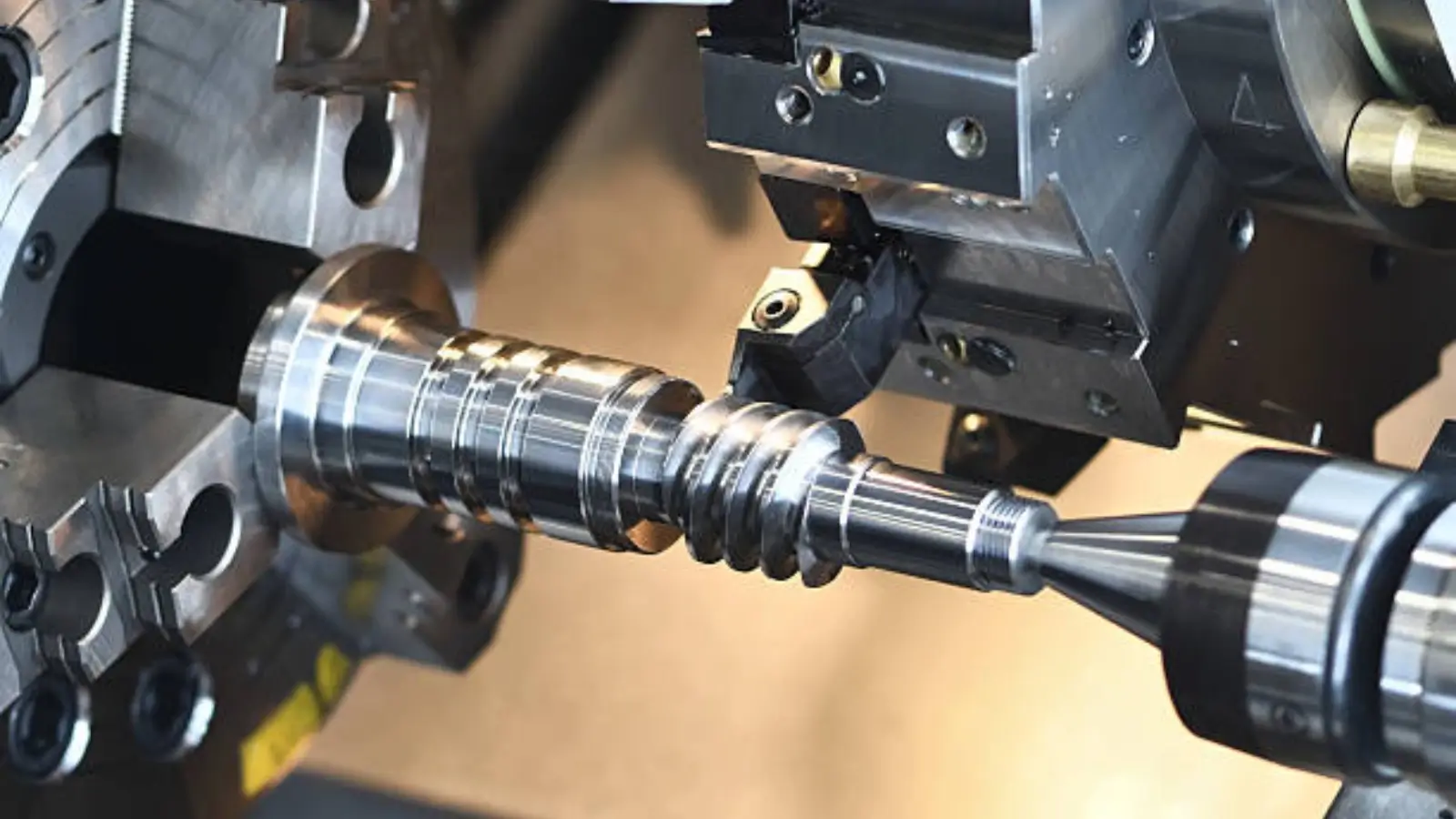

The rise of smart manufacturing has shifted what customers expect from precision-machined parts makers, nudging them toward flexible, quick-reacting, and quality-first work habits. Integrating Automation for Higher Productivity Automation is no longer a luxury-it's a baseline requirement for manufacturers competing in smart industries. CNC turning operations increasingly rely on: * Robotic part-handling systems to cut manual tasks and keep quality steady. * Automatic tool changers and material loaders that smooth the switch between batches. * AI-powered process controls that tweak set points on the fly. For a modern CNC turned-parts firm, automation doesn't just lower costs; it lifts scalability and quality, too. In automotive, aerospace, and medical work alike, the accuracy and repeatability that robots and smart software provide are simply expected.

Data Collection and Predictive Maintenance

One hallmark of a smart factory is the constant stream of data coming from every machine and process. In a CNC turning shop, this information includes:

-

Spindle load, vibration, and cutting force readings monitored in real time

-

Records of tool wear, cycle counts, and idle periods

-

Alerts that signal a part or system is likely to fail before it actually does

With these insights, shops can schedule maintenance on their own terms, cutting surprise shutdowns, extending asset life, and keeping production steady. For precision part makers, that reliability translates to stronger client trust, especially when contracts come with hard deadlines.

Flexibility and Customization: The New Standard

CNC builders no longer live only for long runs of identical parts. Modern customers want quick turnarounds, last-minute design tweaks, and one-off shapes that challenge old setups. To meet that need, makers are:

-

Turning to multi-axis lathes and Swiss-style machines that mill, drill, and turn in a single clamp.

-

Stocking modular tooling and fixtures that slide, snap, or bolt into place in minutes.

-

Running digital twins to preview cuts, tool paths, and likely defects before metal ever meets the cutter.

For a CNC parts shop that hopes to thrive in the smart factory age, raw skill alone won't cut it; it also needs quick, easy adaptability. That kind of bend-not-break flexibility lets precision makers chase niche markets like robotics, chips, and EVs, where every order leans hard on custom specs.

Employee Skill Upgrades and Human-Machine Collaboration

As factories get smarter, people don't vanish; they step into sharper roles. Workers now sit next to robots, steering software screens, spotting trends in data, and tackling high-value duties such as:

-

Tweaking programs for CNC lathes and mills

-

Chasing down root causes of quality slips

-

Adjusting schedules on the fly

To keep pace, many CNC turned-parts shops now fund upskilling classes in digital know-how, data analytics, and safe cobot teamwork. The result is a braver, faster crew that moves in sync with the speed and twist of smart production.

Quality Assurance in a Data-Driven Environment

Quality is still the watchword for every precision shop. Inside smart factories, control moves onto the line through:

-

Inline sensors that check sizes as parts pass

-

Learning models that raise flags before faults

-

Closed-loop feedback that tweaks feeds and speeds

With this tight weave, precision machining suppliers hit tight tolerances and complex forms for premium customers, slashing scrap and rework along the way.

Supporting Sustainability Goals

Sustainable thinking is now front and centre in every modern supply chain. Smart manufacturing pushes this agenda by:

-

Cutting energy use with sharper cutting paths and alerts for idle machines

-

Shrinking scrap through exact tool work and closed-loop recycling

-

Sharpening stock levels via true just-in-time production

CNC turned-part shops that commit to these green habits lower overhead and attract OEMs keen to meet their own ESG promises.

Collaboration During the Design Phase

In a connected factory world, teamwork begins long before first cut. Suppliers now sit with customers early to:

-

Flag designs that will be hard or costly to machine

-

Propose tighter or looser tolerances that still keep quality

-

Run virtual tests that show what works and what does not

By building the part together, precision shops boost performance, slash launch times, and deepen the bond with their customers.

Conclusion: A New Era of Precision and Intelligence

What it means to be a CNC turned-parts maker has changed fast since the smart factory buzz took hold. Today the job is less about holding a micron and more about serving data, speed, agility, and fresh ideas.

Precision parts shops that plug into smart tech can meet today's tougher industry demands. Whether through predictive analytics, cloud integration, or both, the path to staying competitive is clear: build a production floor that thinks ahead, talks in real time, and works together.