The Future of Automation in Australian Manufacturing

— Automation isn’t about replacing human skill, it's about amplifying it for higher productivity, safety, and sustainability in Australian industry.

Introduction

Across Australia, industries are evolving faster than ever before. From automotive plants and packaging facilities to logistics and energy sectors, one concept stands at the heart of this transformation automation.

Automation is no longer a futuristic buzzword. It’s a practical, measurable way for businesses to improve safety, efficiency, and sustainability. With Australian manufacturers under growing pressure to stay competitive in a global market, automated systems have become the foundation of long-term success.

Companies that embrace automation now are setting the standard for how Australian industry will operate in the decades to come.

What Is Industrial Automation?

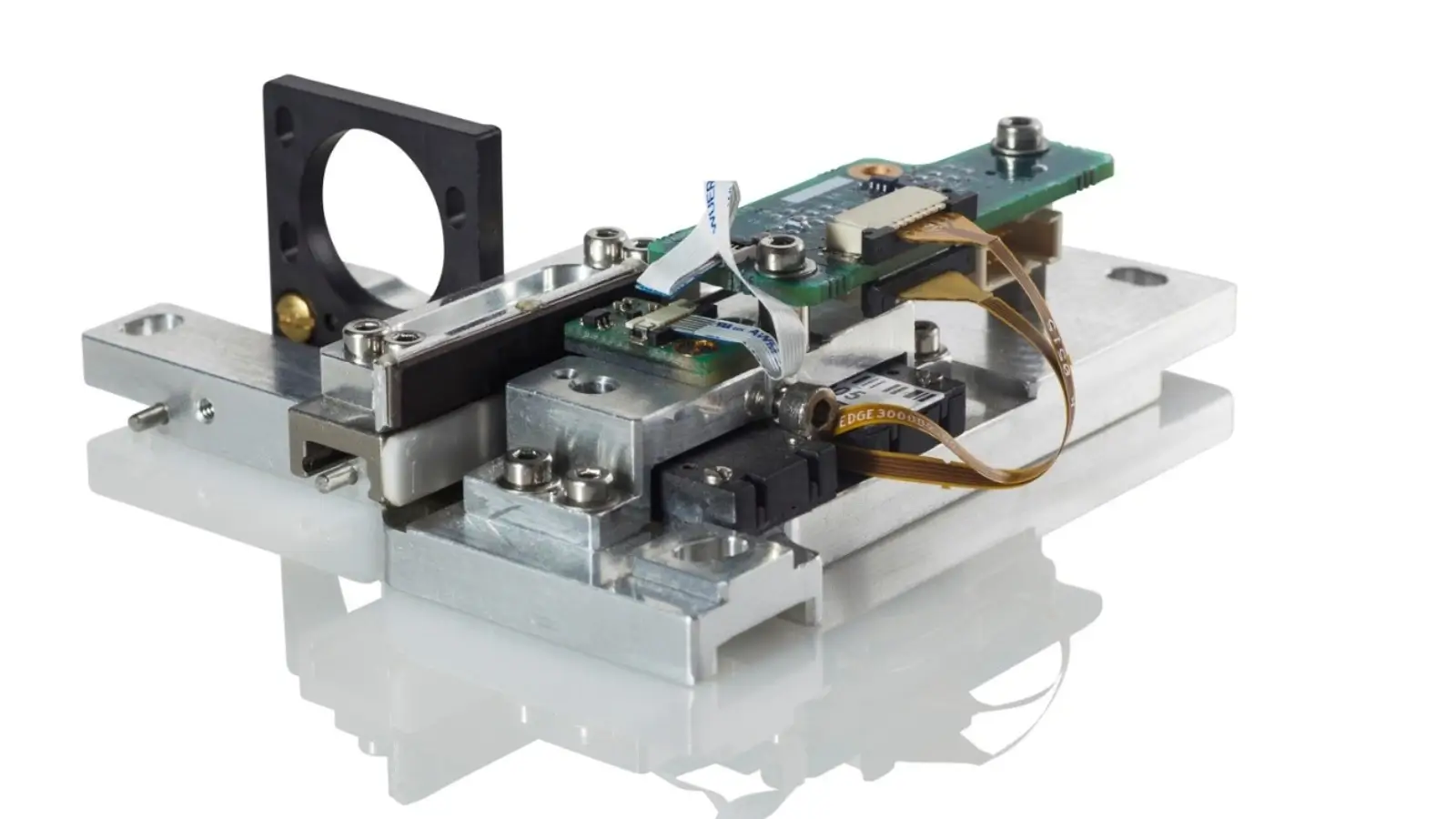

Industrial automation refers to the use of control systems — such as robots, sensors, and software to handle processes with minimal human intervention. The goal isn’t to replace people, but to empower them by streamlining repetitive or hazardous tasks.

Common examples include:

- Automated production lines that maintain consistent quality.

- Robotic assembly systems used in manufacturing and logistics.

- Smart sensors that monitor machinery in real time.

- Data-driven control systems for precision and safety.

Each of these technologies forms part of a wider ecosystem known as Industry 4.0 where machines, data, and human expertise combine for smarter operations.

Why Automation Matters for Australian Businesses

Australia’s industrial landscape is defined by high labour costs and vast geographic distances. Automation helps bridge those gaps through innovation and efficiency.

1. Consistent Quality and Precision

Automated systems perform with exact accuracy, ensuring consistent results in production and packaging. This is particularly important for industries like food processing, electronics, and metal fabrication, where even small deviations can lead to losses.

2. Increased Productivity

Machines don’t need breaks, shift changes, or overtime pay meaning processes can continue 24/7. The result is faster production cycles and improved resource allocation.

3. Safety and Risk Reduction

Automation reduces workplace injuries by taking over high-risk operations such as heavy lifting, cutting, or exposure to chemicals. Smart sensors can also detect hazards before they occur, improving overall workplace safety.

4. Cost Savings Over Time

While the initial investment in automation equipment can be significant, long-term savings through reduced waste, fewer errors, and higher throughput easily offset these costs.

5. Sustainability and Efficiency

Modern automated systems use energy-efficient motors, real-time monitoring, and precision controls to minimise resource use a key factor for businesses aiming to reduce their carbon footprint.

The Role of Automation in the Future of Australian Manufacturing

Australia’s government and private sector are both pushing towards advanced manufacturing models. Automation is central to this shift.

Emerging technologies are transforming the way factories operate:

- Collaborative robots (cobots) that safely work alongside humans.

- Predictive maintenance systems that prevent downtime.

- AI-powered process optimisation, allowing factories to learn and improve autonomously.

- Digital twins, creating virtual models of machinery for real-time simulation and troubleshooting.

Together, these tools improve flexibility, allowing Australian manufacturers to produce more diverse and complex products with shorter lead times.

How Automation Strengthens the Workforce

Contrary to popular belief, automation doesn’t eliminate jobs it changes them. While machines take over repetitive tasks, employees gain opportunities in higher-value areas such as programming, maintenance, and data analysis.

Training programs across Australia are adapting to this reality, teaching new generations of workers how to manage and maintain automated systems. The result is a safer, more skilled workforce capable of leading the next phase of industrial innovation.

Integrating Automation Into Existing Systems

The transition to automation doesn’t happen overnight. A successful integration plan involves several key stages:

- Assessment: Identify bottlenecks and repetitive tasks that can be automated.

- Design: Develop a tailored system that aligns with production needs and safety requirements.

- Implementation: Install hardware and software, integrating with existing infrastructure.

- Testing and Calibration: Ensure all systems operate smoothly under real conditions.

- Training: Equip staff with the knowledge to operate and maintain automated systems effectively.

When implemented strategically, automation enhances both performance and adaptability ensuring a company can scale as demand grows.

Common Myths About Automation

Let’s clear up a few misconceptions:

- “Automation is only for big factories.” Not true. Small and medium businesses can benefit from scalable automation solutions tailored to their budgets.

- “It’s too expensive.” Modular technology and local suppliers have made automation more affordable than ever.

- “It eliminates jobs.” Automation creates new roles in system management, analytics, and engineering.

- “It’s complicated to maintain.” With the right support, modern systems are intuitive and designed for long-term reliability.

Choosing the Right Automation Partner

Implementing automation requires more than just buying equipment it requires expertise. Businesses should look for a partner who understands both technology and industry-specific challenges.

Key qualities to look for include:

- Proven experience across multiple sectors.

- Commitment to Australian standards and safety compliance.

- Strong after-sales service and technical support.

- Ability to provide end-to-end solutions, from concept to installation.

Partnering with specialists like industrial automation experts in Australia ensures every system is designed for efficiency, reliability, and long-term value.

The Road Ahead: Smarter, Greener, Safer

Automation will continue reshaping how Australian industries produce, deliver, and compete. With the right approach, it offers a pathway to:

- Sustainable growth through efficient energy use.

- Enhanced product quality and traceability.

- Greater resilience to labour shortages and supply chain challenges.

The question isn’t whether automation will define the future of manufacturing it’s how soon businesses will adapt. Those that start today are already one step ahead.

Conclusion

Automation isn’t about replacing human skill, it's about amplifying it. By combining innovation with precision, Australian businesses can unlock higher productivity, improved safety, and a more sustainable future.

Working with reliable industrial automation experts in Australia ensures your business is prepared to thrive in a world where efficiency and intelligence go hand in hand.

Automation isn’t just the next step, it's the new standard.