Predictive Maintenance for More Efficient Planning

— “Predictive maintenance enables organizations to optimize resources, reduce downtime, and improve operational efficiency by anticipating problems before they occur.”

Every maintenance manager knows the sinking feeling: a critical piece of equipment fails unexpectedly, grinding operations to a halt. Emergency repair crews scramble, production schedules crumble, and costs spiral out of control. These unplanned failures represent not just immediate repair expenses, but cascading losses in productivity, missed deadlines, and frustrated customers. For decades, organizations have grappled with the question of how to prevent these disruptions without wasting resources on unnecessary maintenance. The answer lies in shifting from reactive firefighting to strategic foresight. Predictive maintenance enables organizations to optimize resources, reduce downtime, and improve operational efficiency by anticipating problems before they occur.

How Predictive Maintenance AI Transforms Operational Planning

The emergence of predictive maintenance AI has fundamentally changed how organizations approach equipment management and planning. Unlike traditional calendar-based maintenance schedules that service equipment at fixed intervals regardless of actual condition, machine learning algorithms analyze vast amounts of historical data, sensor readings, and operational patterns to forecast when equipment failures are likely to occur. Real-time monitoring capabilities provide continuous insights into asset health, detecting subtle changes in vibration, temperature, pressure, or performance that human observers might miss.

This AI-driven approach represents a shift from rigid, time-based schedules to intelligent, condition-based interventions. Instead of replacing a bearing every six months whether it needs it or not, predictive systems can determine that a specific bearing will likely fail in three weeks, allowing maintenance teams to schedule the replacement during planned downtime. The algorithms improve their accuracy over time through continuous learning, becoming more attuned to the specific operating conditions and failure patterns of each piece of equipment.

Key Benefits for Planning and Scheduling

The planning advantages of predictive maintenance extend far beyond simply preventing breakdowns. When maintenance teams know in advance which equipment will require attention and when, they can optimize resource allocation across labor, parts inventory, and budget. Technicians can be scheduled efficiently, with the right skills deployed to the right jobs at the right time. No more pulling specialists off planned projects to handle emergencies.

The reduction in emergency maintenance calls translates directly to cost savings. Emergency repairs typically cost two to five times more than planned maintenance due to overtime wages, expedited shipping for parts, and production losses. With advance notice of impending failures, organizations can order parts at regular shipping rates and schedule work during off-peak hours or planned downtime.

Predictive maintenance also extends asset lifespan by enabling timely interventions before minor issues escalate into catastrophic failures. A small vibration anomaly caught early might require a simple adjustment, while the same issue ignored could lead to complete equipment destruction. This proactive approach protects capital investments and defers expensive replacement costs.

Inventory management improves dramatically when organizations can forecast parts demand with greater accuracy. Instead of maintaining large safety stocks of every conceivable spare part or facing delays while waiting for critical components, predictive systems help right-size inventory based on projected needs. This frees up working capital while ensuring critical parts are available when needed.

Implementation Considerations

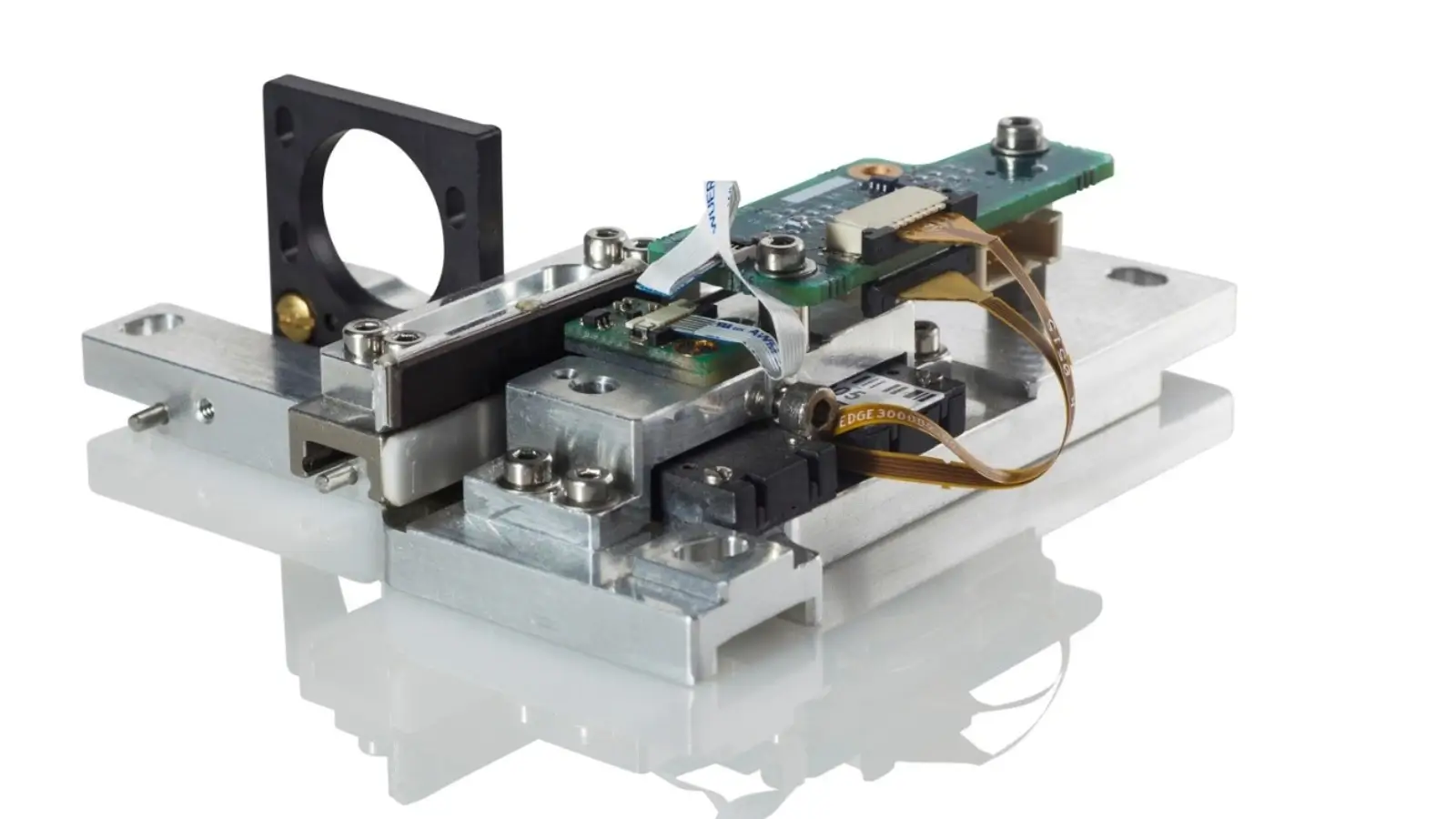

Successfully implementing predictive maintenance requires careful attention to several key factors. The foundation is robust data infrastructure. Equipment must be outfitted with appropriate sensors to capture relevant operating parameters, and systems must be in place to collect, store, and process this data at scale. Organizations need to determine which assets are most critical to monitor and what types of sensors will provide the most valuable insights.

Selecting appropriate AI models depends on equipment types and available data. Some assets may be well-suited to vibration analysis, while others require thermal imaging, oil analysis, or acoustic monitoring. The quality and quantity of historical failure data significantly impacts model accuracy, which means organizations with limited historical records may need to start with simpler rule-based approaches while building datasets for more sophisticated machine learning applications.

Change management represents perhaps the greatest implementation challenge. Maintenance teams accustomed to traditional approaches may be skeptical of AI recommendations, especially when they conflict with years of experience. Successful programs invest in training that helps technicians understand how predictive systems work and how to interpret their outputs. The goal is augmenting human expertise, not replacing it.

Organizations should establish clear ROI metrics from the outset, tracking improvements in uptime, maintenance costs, and asset performance. While predictive maintenance typically delivers positive returns within 12-24 months, benefits compound over time as systems learn and teams become more proficient at acting on insights.

Real-World Applications Across Industries

Manufacturing operations have been early adopters of predictive maintenance, using it to optimize production line availability. A single unplanned stoppage on an automated assembly line can cost thousands of dollars per minute. By monitoring motors, conveyors, and robotic systems, manufacturers can schedule maintenance during shift changes or planned production breaks, maintaining target output levels.

The energy sector relies heavily on predictive approaches for wind turbine fleets and electrical grid infrastructure. Wind turbines operate in remote, harsh environments where unplanned failures are expensive and time-consuming to repair. Predictive systems analyze gearbox vibrations, generator temperatures, and blade performance to schedule maintenance during favorable weather windows when technicians can safely access equipment.

Transportation companies use predictive maintenance to keep commercial fleets on the road. Engine diagnostics, tire wear patterns, and brake system monitoring help fleet managers schedule preventive work that keeps vehicles operating safely while minimizing out-of-service time. This is particularly valuable for companies where vehicle availability directly impacts revenue.

Facilities management teams apply predictive approaches to building systems including HVAC equipment, elevators, and backup generators. Predicting when a chiller might fail allows building managers to schedule replacement before the hottest summer days, avoiding tenant complaints and emergency service calls.

Predictive maintenance has evolved from a novel technology to a strategic imperative for organizations serious about operational efficiency. The ability to anticipate equipment failures and plan maintenance activities accordingly delivers measurable advantages in cost reduction, resource optimization, and operational reliability. As equipment becomes increasingly instrumented and predictive maintenance AI algorithms grow more sophisticated, the accuracy and value of predictive insights will only improve.

Predictive maintenance will increasingly integrate with broader digital transformation initiatives, including digital twins, automated work order systems, and enterprise resource planning platforms, creating seamless workflows that transform maintenance from a cost center into a strategic competitive advantage.