How Businesses Can Streamline Daily Operations With the Right Equipment Mix

— A well-planned equipment mix empowers businesses to streamline operations, reduce downtime, and support sustainable growth.

In a fast-moving business landscape, efficiency is one of the most valuable competitive advantages a company can have. Whether it is a small business handling daily logistics or a large organization managing a complex workflow, the right combination of equipment can significantly reduce downtime, enhance productivity, and support long-term growth. When companies invest in the right tools from the start, they build a solid foundation that allows teams to work smarter and faster while avoiding unnecessary operational bottlenecks.

Understanding the Importance of an Optimized Equipment Mix

The concept of an equipment mix refers to selecting and combining tools, vehicles, and machinery that collectively meet the needs of day-to-day business functions. It is not simply about purchasing the most advanced or expensive technology. Instead, it is about ensuring that each piece of equipment plays a role in achieving a balanced and highly efficient workflow.

Industries such as construction, landscaping, warehousing, and agriculture often rely heavily on their equipment roster. If even one essential machine is missing or not suited for the job, the entire operation can be disrupted. By having a well-planned and versatile equipment mix, companies can keep projects moving, reduce repetitive tasks, and minimize the risk of delays or safety issues.

Assessing Operational Needs Before Making Equipment Decisions

Before businesses make equipment investments, it is essential to conduct a thorough assessment of current needs. This begins with evaluating workflow challenges and identifying areas where productivity stalls. Some equipment may only be used occasionally, while other tools are required daily. Recognizing which tasks are mission-critical helps narrow down which equipment deserves priority in the budget.

Staff capabilities also play a part. If the team requires multiple machines to perform simple tasks, training may become difficult and time-consuming. Understanding who will operate the equipment and how frequently it will be used is crucial in making practical decisions that align with operational goals.

Choosing Versatile Equipment That Supports Multiple Functions

Multi-purpose equipment is becoming increasingly popular as businesses look for cost-effective solutions that deliver maximum value. Machines that can perform different tasks simplify training, reduce storage needs, and lower overall equipment expenses. This versatility also enables teams to adapt quickly when business needs shift or seasonal tasks arise.

For example, a single piece of equipment that handles loading, hauling, and lifting eliminates the need for separate tools and reduces the amount of maintenance required throughout the year. Businesses benefit from streamlined operations and a workforce that can complete more tasks with fewer resources.

The Role of Compact Utility Vehicles in Daily Operations

Compact utility vehicles have become indispensable in many industries because of their ability to handle a wide range of jobs with ease. They are small enough to navigate tight spaces yet powerful enough to carry loads, transport materials, and support various attachments. Many businesses also appreciate their reliability and fuel efficiency.

Within this category, a kei truck is often a standout choice for companies seeking a practical and compact vehicle that fits seamlessly into everyday operations. Its small footprint, light handling, and strong utility capabilities make it suitable for landscaping crews, construction teams, agricultural work, and facility maintenance. For businesses that need mobility, hauling capacity, and versatile application, compact utility vehicles can quickly become one of the most valuable pieces of equipment in the entire fleet.

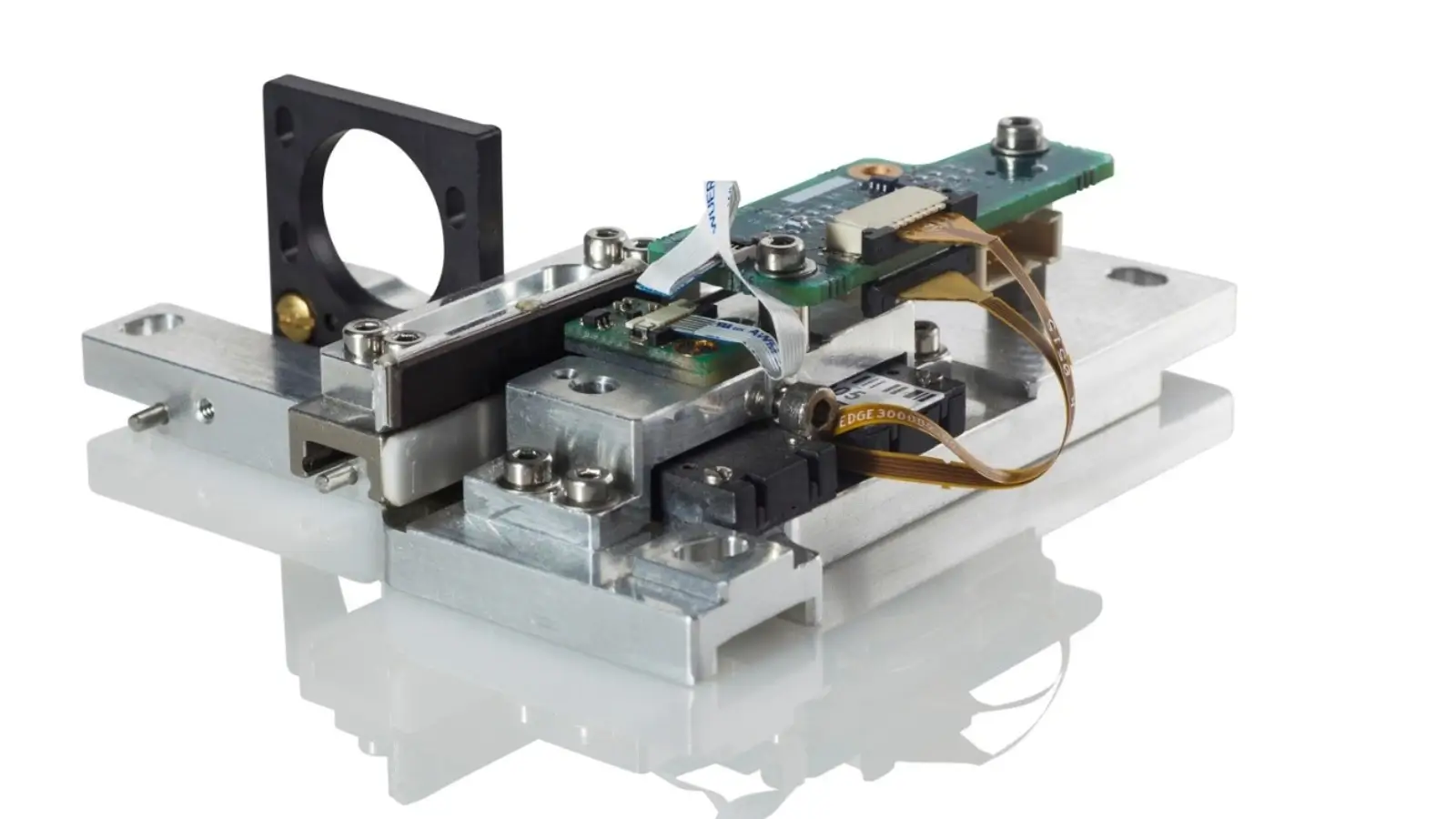

Integrating Technology and Smart Features Into Your Equipment Strategy

As technology advances, businesses have more opportunities to enhance their equipment strategies with intelligent features. Telematics solutions, smart monitoring tools, and automated performance tracking systems help companies understand how equipment is being used and where potential inefficiencies lie. These technologies also make predictive maintenance more accessible, reducing the risk of unexpected breakdowns and extending equipment lifespan.

Modern equipment equipped with smart capabilities allows businesses to plan proactively. Instead of waiting for a problem to arise, systems can alert operators when maintenance is due or when performance drops, improving overall safety and operational readiness.

Budgeting and Long-Term Planning for Equipment Upgrades

Creating a strategic budgeting plan ensures that businesses can invest in the equipment they need without straining finances. This involves evaluating the balance between cost, quality, and expected usage. In some cases, renting or leasing equipment may be more practical than purchasing outright, especially for seasonal tasks or large specialty machines.

Long-term planning also means forecasting business growth and anticipating future needs. Companies that prepare for evolving demands can avoid emergency purchases and make smarter, well-researched investment decisions that support long-lasting operational stability.

Case Examples of Businesses Improving Efficiency With the Right Mix

Real-world scenarios show how an effective equipment mix can transform workflow outcomes. A landscaping company may significantly cut project times by introducing compact utility vehicles, while a fulfillment center might benefit from investing in multi-function handling equipment. These improvements do not just increase productivity. They also enhance employee satisfaction and reduce the risk of burnout by simplifying physically demanding tasks.

Final Insights for Building an Efficient Equipment Strategy

Creating an effective equipment mix is more than selecting tools. It is about designing a long-term operational strategy that supports productivity, safety, and adaptability. By choosing versatile equipment, integrating smart technology, and planning ahead for upgrades, businesses can streamline daily tasks and avoid unnecessary disruptions. A well-planned equipment strategy empowers companies to meet challenges with confidence and positions them for continued growth and efficiency in the years ahead.