Rotomoulding is ideal wherever reliability, economy, and maximum efficiency are required. This method of manufacturing plastic components has grown in popularity in recent years, which is why we have prepared an article discussing the phenomenon of rotational moulding. Would you like to know why it is worth choosing rotomoulding for your manufacturing company? Stay with us a little longer and find the answer to this question. We guarantee that you will not be disappointed with rotomoulding!

Let's start with something that is a key aspect of choosing a production technology for many entrepreneurs. This comes as no surprise to us, as the quality of the items you purchase should be one of the priorities of your business. Rotomoulding guarantees the best: mechanical durability, visual durability, and zero risk of manufacturing defects. As a result, rotomoulded products, regardless of their type or method of use, outperform alternatives in virtually every respect!

Although the initial cost of investing in rotomoulding machines seems high, in the long run, using this type of technology simply pays off. This is especially true when it comes to small or medium-sized production runs. Lower expenditure promotes economy, although material consumption is still really optimal in this case. The same can be said about the costs of rotomoulding moulds. If we consider alternative methods of producing plastic components, the rotomoulding mould really stands out with its competitive prices.

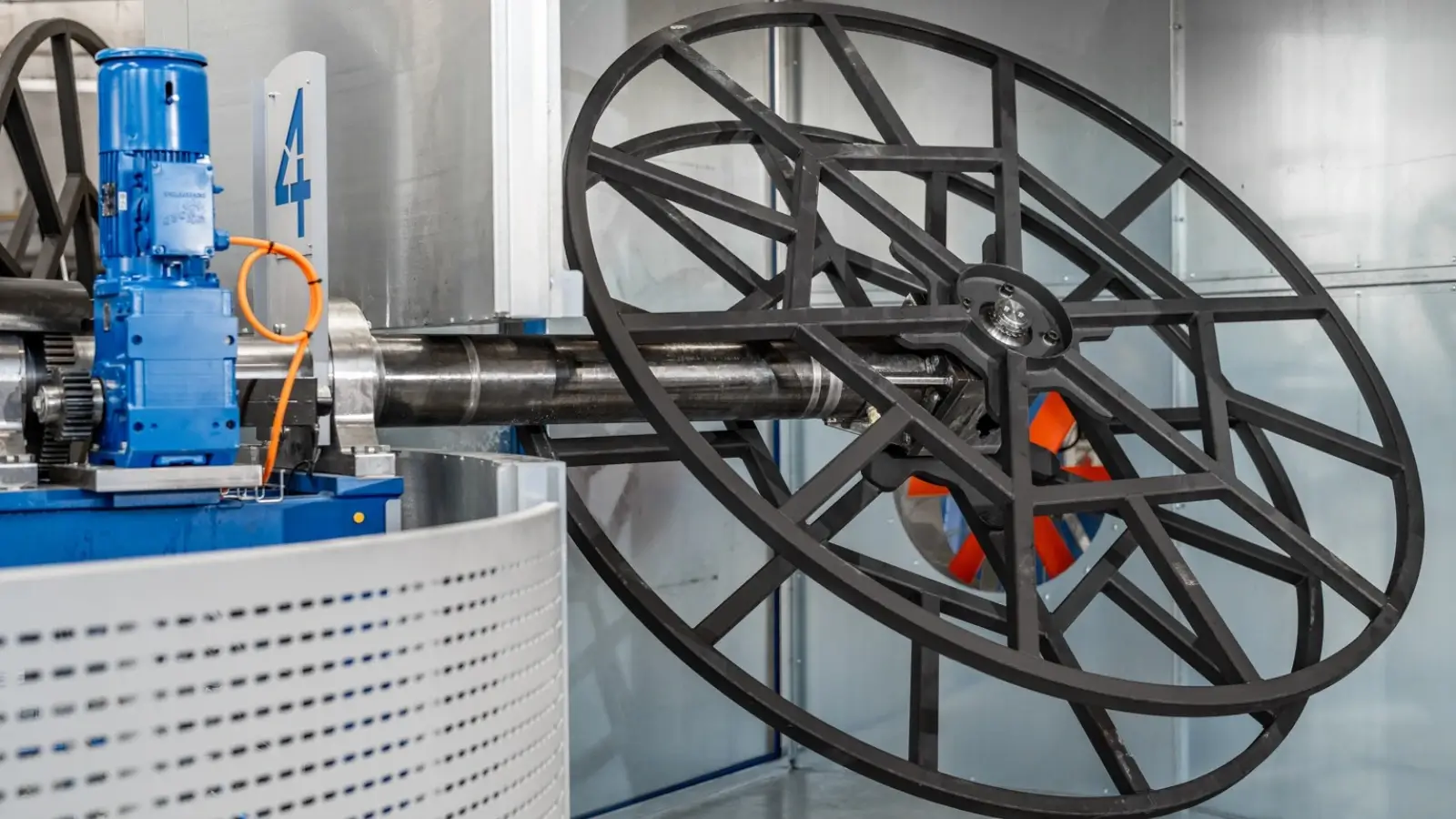

And in this case, we are not just talking about the appearance of the machines or the possibility of operating them using a built-in computer. In fact, this is a standard that is easy to get used to. The vast majority of similar solutions already use this type of convenience. However, rotomoulding goes a step further and offers modernity in the form of optimized operation. By choosing rotomoulding, you are choosing an ecological approach to the production of various components. Does a significantly reduced amount of energy consumption sound good? You should know that this is not all. The most reputable companies responsible for creating such machines, including OREX ROTOMOULDING, also guarantee a reduction in the amount of harmful substances released into the atmosphere and the complete elimination of waste from the material used to fill the rotomoulding mould. The combination of the factors mentioned above will certainly appeal to anyone who cares about the well-being of the natural world around us. No more straining it!

Many experts praise rotomoulding for its universal approach to the production of various plastic products. And they are quite right, because rotational molding allows not only large, hollow structures to be created, but also objects with unusual shapes. This makes it a method that has a truly wide range of practical applications. For many years, we have been observing the development of rotomolding in sectors such as:

construction,

road architecture elements,

automotive and transport,

active leisure and sports,

renewable energy,

garden and allotment equipment.

This only shows how important rotomoulding is in everyday life. There are also many indications that, over time, rotational molding will serve society by enabling even wider use of this type of product. More and more manufacturers are taking a closer look at the method discussed here. And the advantages mentioned above are only beginning to distance rotational molding from alternative methods of manufacturing plastic components. In a positive sense, of course.

The list of the biggest advantages of rotomoulding already looks impressive. However, it is worth bearing in mind that this is only the beginning of the development of the rotational moulding method. Although it has been present in our lives for decades, it is only now that we are seeing the full blossoming of a modern approach to the production of plastic components. It is already safe to assume that in the coming years, rotomoulding will gain in functionality and begin to appear more frequently in urban spaces, in specialized plants, and in other sectors of our economy. It is also almost certain that processes will be streamlined. Optimizing work has always been a priority for companies designing rotomolding machines. We are referring primarily to production time and the number of products generated. The issue of machine operation by a specialist is also important. It is precisely these areas that will be the focus of those responsible for designing and building machines. That is why it is worth jumping on the rotomoulding bandwagon now and starting to use the best and most suitable plastic component manufacturing process for your needs. The satisfaction of your end customers will be the best form of advertising.