In a busy workshop, even the smallest mistake can lead to big consequences. A skipped step in engine assembly, a wrong part number during repairs, or a missed torque specification; these errors don’t just slow down the job. They cost time, affect trust, and eat into profits.

Most of these issues trace back to outdated or hard-to-read documentation. When you're flipping through greasy, worn-out manuals or relying on memory, the chances of missing a detail are high. That’s where a PDF Workshop Service Manual offers a practical advantage. This digital solution helps streamline your tasks, improves accuracy, and saves time with each job you take on.

What Is a PDF Workshop Service Manual?

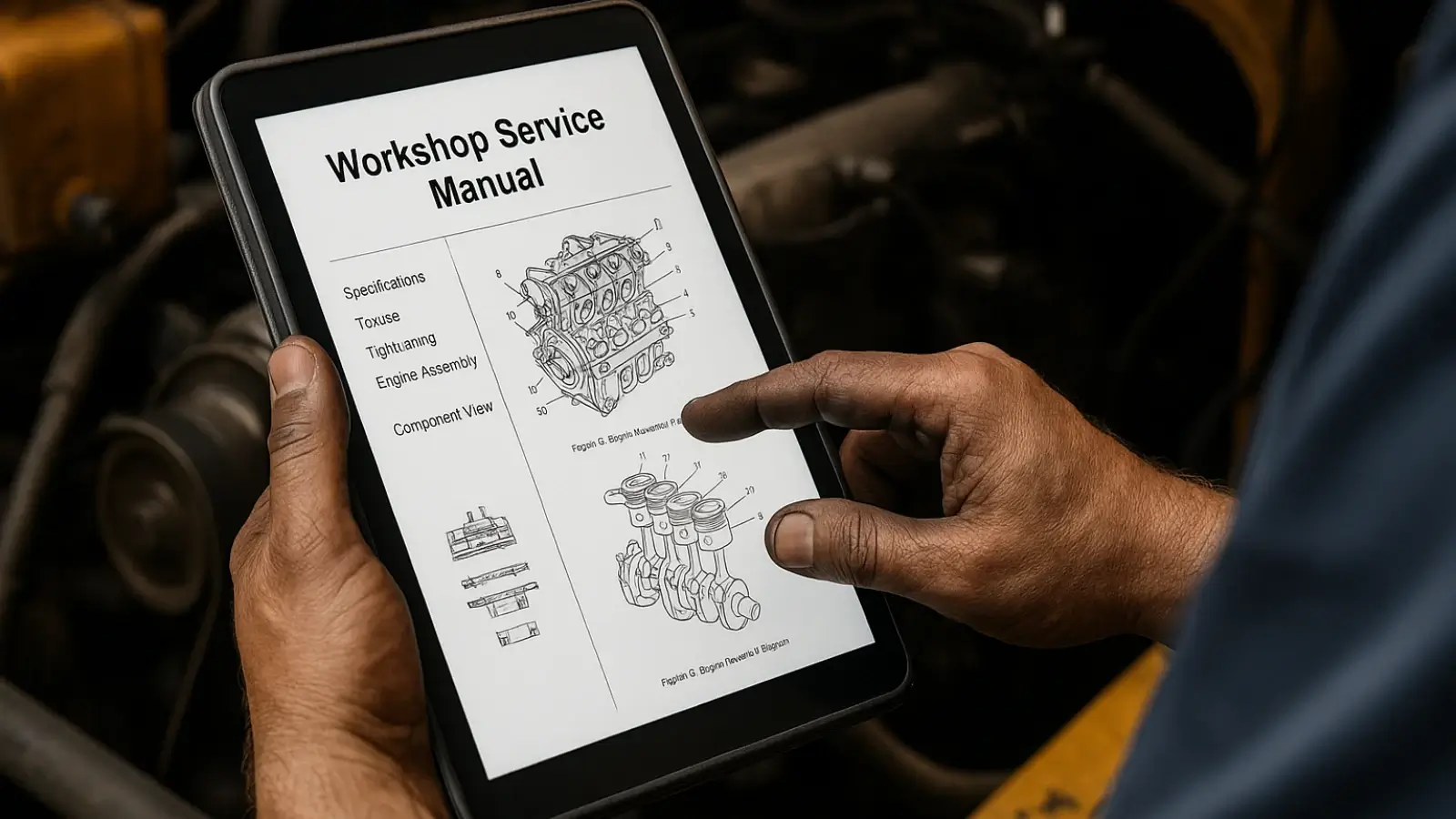

A PDF Workshop Service Manual is a digital file containing complete technical information, schematics, procedures, and part numbers for maintaining or repairing equipment. It may include color-coded wiring diagrams, torque specs, fluid types, service intervals, diagnostic steps, and exploded views of components.

Unlike paper manuals that wear out or go missing, this format stays accessible. You can store it on your tablet, workshop PC, or even your phone. Whether you’re servicing tractors, loaders, forklifts, or industrial machinery, having the manual in digital form means you’re always ready, without needing a paper backup.

These manuals are often provided by manufacturers or trusted third-party sources. They follow precise formatting so that technicians can scan through instructions quickly, jump to the right section, and locate technical data without second-guessing.

Time-Saving Benefits for Busy Technicians

When work piles up and every minute counts, a PDF-based service guide becomes more than just a convenience; it becomes part of your efficiency strategy.

Here’s how it helps:

-

Quick Searches: You can type keywords directly into the file’s search bar. There’s no need to flip pages one by one or rely on memory.

-

No Downtime for Lost Pages: Paper manuals often end up misplaced, torn, or stained. With a PDF version, you’re never stuck hunting for information.

-

Instant Zoom on Diagrams: Need to double-check a wiring connection or hydraulic layout? Zoom in with ease and see it clearly without squinting.

For those managing large fleets or multiple job types, having all your manuals organized in a single folder saves hours across a workweek. A well-used PDF Workshop Service Manual becomes a trusted tool for keeping pace with demand.

How It Supports Accurate Diagnostics and Repairs

Mechanical work isn't trial and error. It's about precision, knowing the exact torque rating, choosing the correct replacement part, or following a diagnostic flowchart that leads you to the right solution.

Here’s where these manuals step in:

-

They list diagnostic trouble codes (DTCs) and provide steps to resolve them.

-

They offer clear tables for torque specifications, fluid types, and part IDs.

-

Some versions come with linked sections, so if you're reading about an engine issue, you can click straight into the relevant component diagram.

Instead of guessing or relying on secondhand advice, you’re working with verified technical data. With every repair done right the first time, customer satisfaction improves, and workshop rework is reduced.

Why Digital Manuals Outperform Paper Guides

Printed service books had their place—but in today’s work environments, they slow things down. Between smudged diagrams, out-of-date procedures, and missing appendices, they can create more hassle than help.

Digital manuals offer several key advantages:

-

Up-to-date content: Manufacturers can update digital files as they release new service bulletins or part changes.

-

Portability: Access them from multiple devices, including laptops and tablets placed right next to your workstation.

-

Less clutter: Replacing stacks of binders with a digital library clears up shelf space and keeps your environment more organized.

Some workshops even go a step further by integrating their PDF Workshop Service Manual files into cloud platforms. This allows teams to collaborate and access technical data from different locations, ensuring continuity in both large and small operations.

Practical Use Cases in Modern Workshops

Let’s look at a few scenarios where digital manuals make the most impact:

1. Diagnosing Hydraulic Leaks

A technician working on an excavator notices pressure drops in the boom cylinder. Rather than manually tracing each hydraulic line, they check the PDF diagrams for pressure test ports and flow paths. Within minutes, the problem is located and resolved.

2. Replacing a Transmission Component

With access to exploded diagrams and bolt sequences in the manual, the mechanic avoids misalignments during reassembly. The job finishes faster, and there's no need for rework.

3. Working with New Hires

Training junior staff becomes easier. They can open the PDF Workshop Service Manual, follow clear instructions with illustrations, and perform tasks without needing constant supervision.

These manuals aren't just reference tools—they’re learning tools, troubleshooting aids, and time management assistants all rolled into one.

Choosing the Right Format and Source

Not all digital manuals are created equal. Some are just scanned images of printed books, which lose their value when they can’t be searched. Others are poorly labeled or missing key sections.

When selecting a service manual for your equipment:

-

Make sure it is searchable and comes with bookmarks or an indexed table of contents.

-

Choose manuals that include color-coded diagrams for better visual clarity.

-

Verify the manual matches your equipment model, year, and configuration.

-

Prefer official documentation from manufacturers or authorized technical publishers.

Final Thoughts

Modern workshop operations need more than experience, they need the right tools to back up that experience. A PDF Workshop Service Manual provides reliable, quick access to accurate technical data, helping mechanics avoid costly mistakes and wasted time.