What Manufacturing Founders Should Know About Component Sourcing

— Component sourcing plays a central role in manufacturing success—it affects reliability, timelines, and customer trust.

Manufacturing founders usually focus on building a strong product, winning customers, and increasing sales. These priorities make sense, especially in the early stages of a business. However, component sourcing often remains an afterthought until problems begin to surface.

A delayed shipment, inconsistent quality, or a supplier failing to deliver can quietly disrupt production. These issues rarely feel urgent at first, but they slowly weaken operations.

As manufacturing businesses grow, sourcing decisions become harder to undo. Higher production volumes increase pressure on supply chains. Lead times tighten. Customers expect reliability.

In competitive markets, even minor disruptions can cause missed deadlines, rising costs, and damaged trust. Founders who overlook sourcing strategy often struggle to maintain consistency as they scale.

In this article, you’ll learn what manufacturing founders should understand about component sourcing and how it helps!

Understanding Supplier Reliability and Compatibility

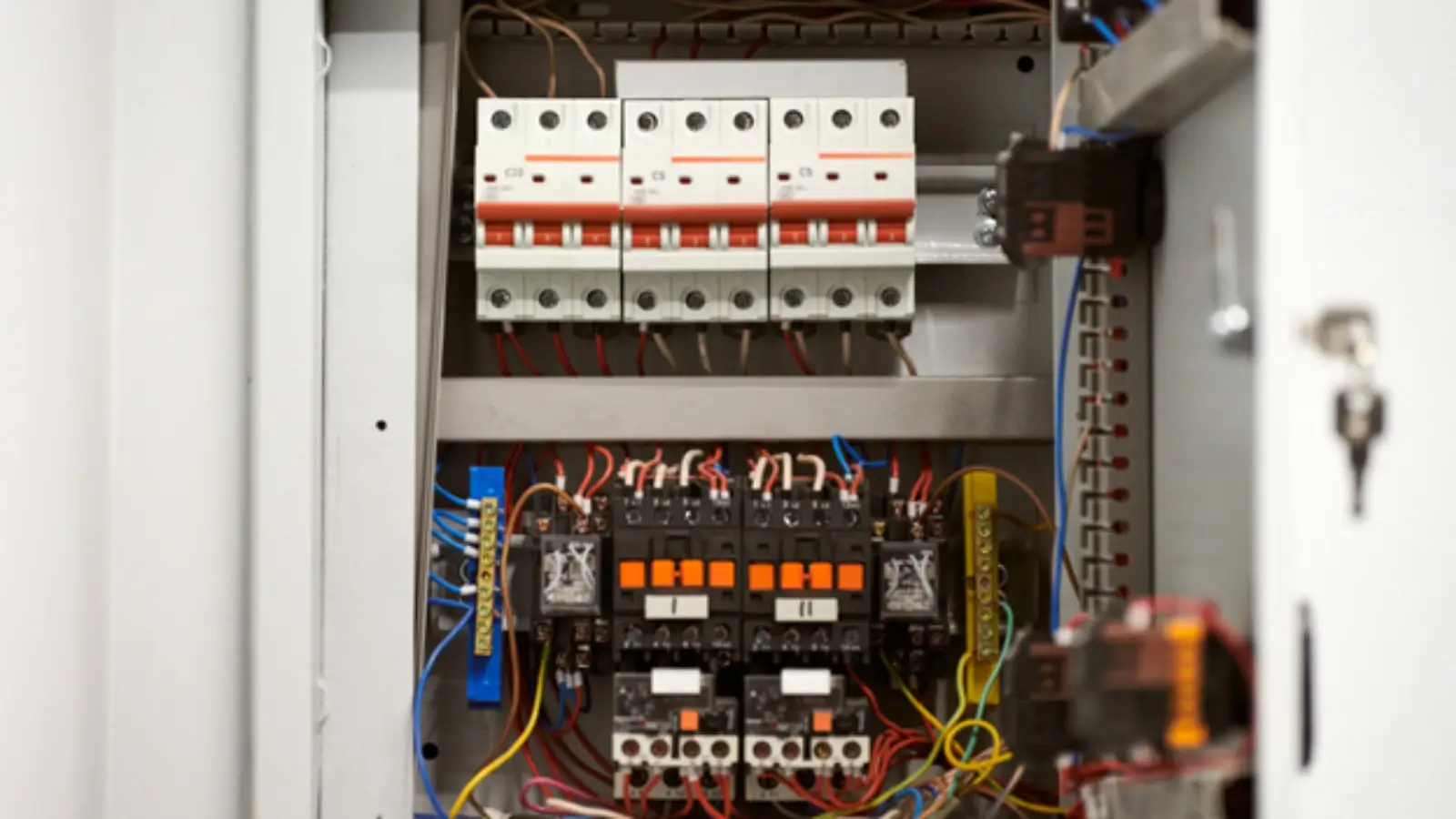

Manufacturing operations rely on both new components for production builds and compatible parts for ongoing equipment use. As systems evolve and machines remain in operation longer, founders must ensure that sourced components align with existing specifications without disrupting workflows.

Compatibility becomes especially important when components are integrated into established designs or standardized equipment setups.

Battery-powered systems are common across manufacturing environments, especially in equipment designed for consistent, repeated use. These systems require batteries that match the original design in terms of size, power output, and fit. Even small differences can affect performance or interrupt routine operations during assembly or servicing.

For example, for machines built around Dyson-based systems, manufacturers typically look for compatible battery options that align with existing specifications. In such cases, a Rhybattery Dyson battery pack is often referenced as an industry-compatible option that supports continuity without requiring changes to equipment design or maintenance workflows.

This approach allows manufacturing teams to maintain operational stability while sourcing components that fit both new builds and ongoing equipment needs.

Founders should still assess suppliers using practical criteria, including:

- Consistency across production batches

- Availability of technical specifications

- Responsiveness during integration issues

- Experience supporting similar equipment environments

Reliable sourcing decisions reduce disruption and support steady manufacturing operations.

Balancing Cost, Quality, and Production Timelines

Cost control remains a constant challenge for manufacturing founders. Choosing the lowest-priced component may appear efficient initially, but it often leads to higher long-term costs. Poor-quality components can cause rework, returns, and warranty claims. Delays disrupt schedules and increase labor expenses.

Manufacturing founders should evaluate the total cost rather than the unit price. Total cost includes the financial impact of downtime, quality failures, and missed delivery commitments. A slightly higher upfront cost often results in fewer disruptions and better overall margins.

Important factors to compare when sourcing components include:

- Quality standards and certifications

- Lead times and delivery reliability

- Consistency across production batches

- Availability of technical support

Production timelines depend heavily on predictable sourcing. When suppliers fail to meet schedules, the entire production chain slows down. Balancing cost with reliability helps founders protect timelines while maintaining quality standards.

Managing Supply Chain Risk as the Business Scales

Scaling manufacturing operations introduces new risks. Higher volumes leave less room for error. A single delayed shipment can halt production lines. One faulty batch can affect hundreds of units. Founders must reassess sourcing strategies as operations grow.

Risk management begins with visibility and communication. Clear expectations help suppliers prepare for increased demand. Regular quality checks reduce surprises during scaling. Backup suppliers protect operations from sudden disruptions.

Common risks founders should plan for include:

- Supplier capacity limitations

- Raw material shortages

- Transportation delays

- Regulatory or compliance changes

Inconsistent batches pose a greater threat during scale. A defect affecting a small run may be manageable. The same issue affecting large volumes can damage customer trust and strain finances. Proactive sourcing decisions help founders avoid these setbacks before they escalate.

Building Long-Term Supplier Relationships

Transactional sourcing works during experimentation phases. It becomes risky during growth. Manufacturing founders benefit from building long-term relationships with suppliers who understand evolving production needs. Trusted suppliers adapt as volumes change and requirements become more complex.

Long-term partnerships improve communication and problem-solving. When issues arise, established suppliers respond faster and collaborate on solutions. They also provide better insights into lead times, customization options, and future capacity planning.

Benefits of strong supplier relationships include:

- Faster issue resolution

- More consistent quality

- Better alignment with production goals

- Improved supply predictability

These partnerships reduce operational stress and support accurate planning. Over time, reliable relationships help founders maintain stability even during rapid expansion.

Why Founders Should Revisit Sourcing Decisions Regularly

Component sourcing is not a one-time decision. Markets shift. Demand changes. New regulations emerge. Suppliers that worked well in the past may struggle to keep pace with growth. Founders should review sourcing strategies regularly to ensure alignment with current goals.

Regular reviews help identify emerging risks and improvement opportunities. They also encourage suppliers to maintain standards and transparency. Continuous evaluation supports resilience in competitive environments where disruptions are common.

Conclusion

Component sourcing plays a central role in manufacturing success. It affects reliability, timelines, and customer trust. Founders who treat sourcing as a strategic function gain greater control as operations scale. Reliable suppliers, compatible components, and balanced cost decisions reduce risk and improve consistency. Strong supplier relationships further support long-term stability. In competitive markets, thoughtful sourcing choices help manufacturing businesses grow confidently while protecting quality and reputation.