Maintaining the correct temperature in industrial machinery is a fundamental aspect of ensuring optimal performance and avoiding equipment breakdowns. Thermal management plays a crucial role in predictive maintenance by helping businesses identify potential issues before they lead to costly failures. Through a combination of advanced thermal techniques and tools, industrial facilities can improve uptime, reduce the risk of unexpected repairs, and extend the operational lifespan of equipment. Here’s how thermal management works in the context of predictive maintenance.

Thermal imaging, also known as thermography, is one of the most widely used techniques for predictive maintenance. This non-invasive method uses specialized thermal cameras to detect infrared radiation emitted by objects. By capturing thermal images, maintenance teams can detect temperature variations, hotspots, and areas of excessive friction or electrical faults. These thermal anomalies help technicians take preventive action by adjusting cooling systems, lubricating moving parts, or scheduling repairs ahead of time. This proactive approach minimizes unplanned downtime and reduces maintenance costs.

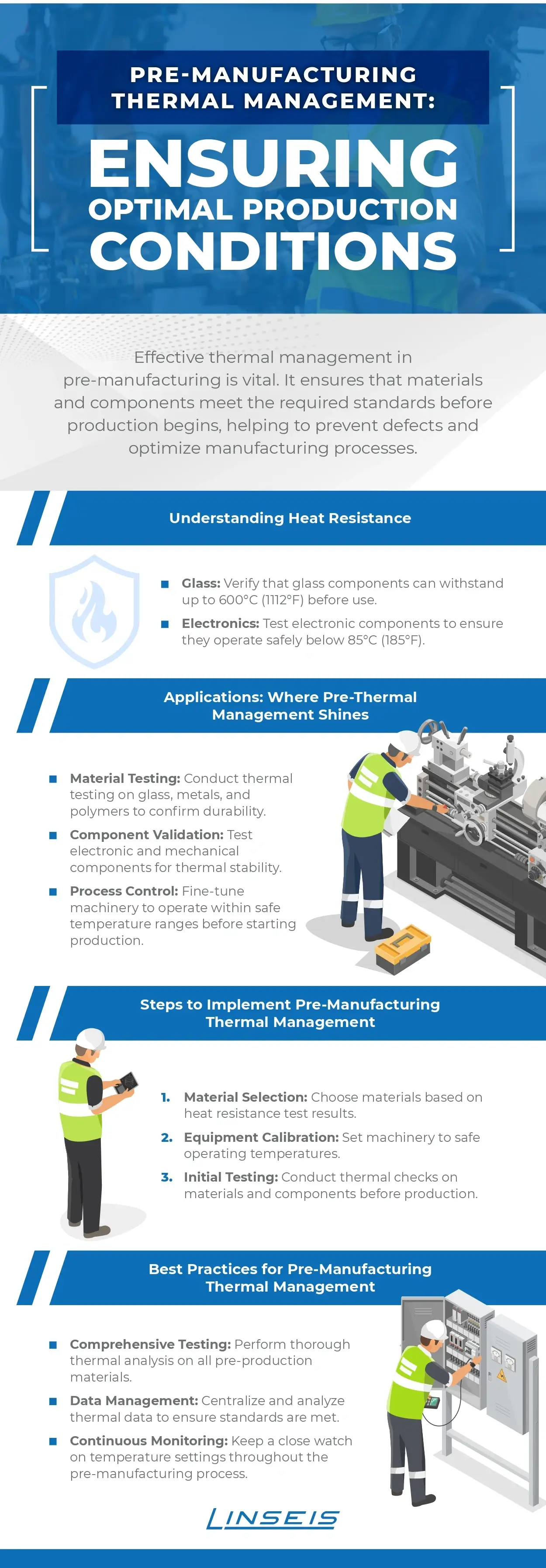

In addition to thermal imaging, it’s essential to understand the heat resistance properties of materials used in industrial applications. For example, borosilicate glass, which can withstand temperatures up to 932°F (500°C), is commonly used in high-temperature environments. For even more demanding conditions, advanced glass-ceramics such as PyroCeram® and NeoCeram® are designed to withstand temperatures up to 1470°F (800°C). This higher level of thermal stability is critical for maintaining the integrity of equipment and ensuring that high-heat components continue to perform optimally.

Electronic components in industrial machinery also have strict temperature operating ranges. Overheating can cause malfunctions, reduced performance, and permanent damage. By using techniques like thermography and monitoring temperature over time, maintenance teams can help ensure these components stay within safe temperature limits, boosting reliability and performance.

Incorporating thermal management into predictive maintenance requires regular inspections and data analysis. Periodic thermal scans, combined with vibration analysis and motor circuit analysis, provide a comprehensive view of the equipment’s health. These combined insights enable more accurate predictions of failures, which improves the efficiency of maintenance schedules and enhances overall equipment reliability.

Moreover, proper training and expertise are vital for effective thermal management. Maintenance personnel must be well-versed in using thermal imaging tools and interpreting data accurately. Regular training and education help ensure teams stay up to date with the latest advancements in thermal management, ensuring ongoing improvements in equipment maintenance and performance.

In conclusion, predictive maintenance powered by thermal management is essential for maintaining the operational efficiency of industrial machinery. By staying ahead of potential issues and addressing them proactively, businesses can reduce downtime, avoid costly repairs, and maximize the lifespan of their equipment. With thermal imaging, material heat resistance knowledge, and well-trained staff, companies can manage thermal concerns effectively and maintain high standards of operational excellence.

A thermogravimetric analyzer can also be a valuable tool for assessing the material properties and behavior of certain components under varying temperature conditions, ensuring they remain stable and reliable in industrial environments.