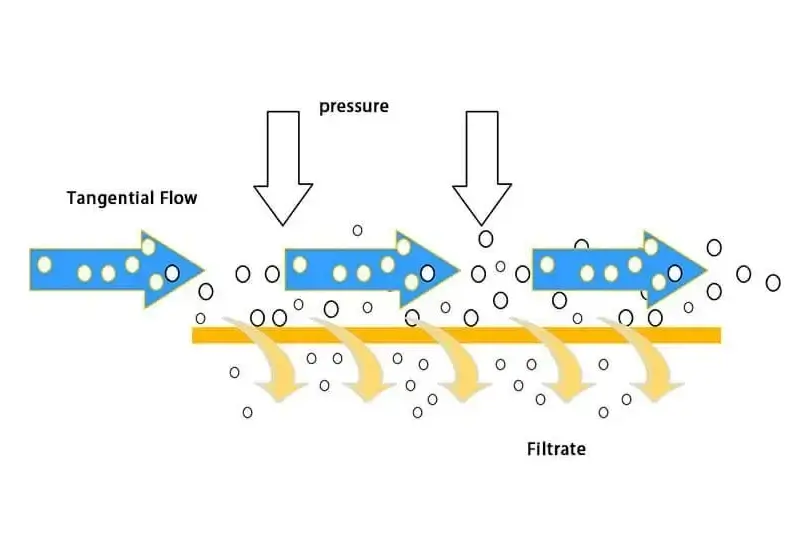

The Core Mechanism of Tangential Flow Filtration

Tangential flow filtration, often called cross-flow filtration, is a method that separates molecules based on size using a membrane. Instead of pushing the liquid straight through the membrane, the liquid flows across its surface. This tangential movement is key. It helps keep the membrane clean by sweeping away particles that might otherwise clog it. This process allows for continuous operation, concentrating or purifying your product over time.

Tangential Flow Filtration Versus Normal Flow Filtration

Normal flow filtration, also known as dead-end filtration, is like using a sieve. You push the liquid directly at the filter, and everything larger than the pores gets stuck, forming a cake. This cake quickly slows down or stops the flow. Tangential flow filtration, however, flows the liquid parallel to the membrane. Only a portion of the liquid passes through. The rest flows across the surface, preventing that cake buildup. This means tangential flow filtration can handle more material and run for longer periods without losing efficiency.

Key Components of a Tangential Flow Filtration System

A typical tangential flow filtration setup involves several parts working together. You have a feed reservoir holding the liquid. A pump is used to move this liquid at a controlled rate. The heart of the system is the membrane module, which can be a cassette or hollow fibers. Pressure sensors monitor the system, and a valve on the retentate line helps control the pressure across the membrane. All these pieces work in a loop to achieve the desired separation. The goal is to maintain a steady flow and pressure for effective filtration.

Automation Enhancements in Tangential Flow Filtration

Traditional tangential flow filtration (TFF) often involves manual adjustments and fixed settings. This can lead to process variability and suboptimal outcomes. Automation steps in to address these limitations, bringing greater control and efficiency to TFF operations. By automating key parameters, manufacturers can achieve more consistent results and reduce the risk of human error.

a) Addressing Challenges in Traditional Tangential Flow Filtration

Manual operation of TFF systems can be demanding. Operators must constantly monitor pressures, flow rates, and permeate volumes. Adjustments are often made based on experience rather than real-time data. This can result in inefficient processing, membrane fouling, and inconsistent product quality. Automation provides a solution by taking over these monitoring and adjustment tasks.

b) Hybrid Models for Real-Time Tangential Flow Filtration Optimization

Hybrid models combine the strengths of traditional TFF with advanced analytics. These models use real-time data from the TFF system to predict performance and make automatic adjustments. This allows for continuous optimization of parameters like transmembrane pressure (TMP) and cross-flow rate. The goal is to maintain peak filtration efficiency throughout the process, leading to higher yields and better product consistency. This approach to tangential flow filtration is transforming how processes are managed.

c) Digital Twins and Advanced Analytics for Process Improvement

Digital twins create virtual replicas of physical TFF systems. These models can simulate different operating conditions and predict outcomes without affecting the actual process. Advanced analytics applied to data from both the physical system and its digital twin can identify trends and areas for improvement. This data-driven approach allows for proactive maintenance and process fine-tuning, further boosting the performance of automated tangential flow filtration.

Benefits of Automated Tangential Flow Filtration

a) Achieving Higher Product Yields and Consistency

Automated Tangential Flow Filtration (TFF) systems bring a new level of precision to bioprocessing. By maintaining consistent operating parameters, these systems minimize batch-to-batch variability. This consistency directly translates to higher product yields, as less material is lost due to process fluctuations. The tangential flow action itself is gentle on many biomolecules, preventing degradation and ensuring more of the valuable product remains intact and recoverable.

This improved consistency is a major win for manufacturers. It means that every batch produced meets the same high standards, reducing the need for costly reworks or product re-specification. The automated control over factors like transmembrane pressure and cross-flow rate means that the filtration process is always operating within its optimal window, maximizing both yield and purity. This level of control is hard to achieve with manual operations.

b) Improving Process Stability and Reducing Operating Costs

One of the most significant advantages of automated TFF is its impact on process stability. Traditional manual operations are prone to human error, leading to unpredictable performance and potential downtime. Automation eliminates these variables, creating a more robust and reliable filtration process. This stability means fewer interruptions and a more predictable workflow.

Furthermore, automation leads to substantial cost reductions. By optimizing membrane performance and reducing the frequency of cleaning or replacement cycles, operating expenses are lowered. The reduced labor requirements also contribute to cost savings. Automated Tangential Flow Filtration systems are designed to run efficiently for extended periods, minimizing waste and maximizing throughput.

c) Streamlining Operations Through Advanced Control

Automated TFF systems simplify complex filtration tasks. Advanced control algorithms manage critical parameters, allowing operators to focus on other important aspects of production. This streamlines the overall operation, making processes more efficient and less labor-intensive. The ability to integrate with other automated systems further enhances operational efficiency.

These systems offer real-time monitoring and data logging, providing valuable insights into process performance. This data can be used for continuous improvement and troubleshooting. The precise control offered by automation means that processes can be fine-tuned to achieve specific separation goals with greater accuracy than ever before. This makes Tangential Flow Filtration a more accessible and powerful tool for a wider range of applications.

Scalability and Equipment Considerations for Tangential Flow Filtration

a) Scaling Tangential Flow Filtration from Lab to Commercial Production

Moving tangential flow filtration (TFF) from the lab bench to full-scale production requires careful planning. The good news is that TFF principles scale well. Key parameters like cross-flow velocity and transmembrane pressure can be kept consistent. This means a process developed with a small TFF system should perform predictably when scaled up. It’s not just about bigger equipment; it’s about maintaining the same fluid dynamics and separation efficiency.

Consistency is key when scaling TFF operations. You want the same separation performance, whether you’re processing milliliters or thousands of liters. This predictability helps avoid costly re-development work.

Think about the feed material. As volumes increase, so does the potential for particulates. Pre-filtration becomes even more important at larger scales to protect the main TFF membranes.

b) Selecting Appropriate Tangential Flow Filtration Equipment

Choosing the right TFF equipment depends on your specific needs. The two main types of TFF modules are cassettes and hollow fibers. Cassettes, essentially flat membranes in a holder, are often easier to clean and handle for shear-sensitive products. They offer good flexibility for different process volumes.

On the other hand, hollow fiber modules are bundles of small tubes. They have a lower internal volume, which can be beneficial for high-value products where minimizing hold-up is critical. However, they can sometimes be more prone to fouling with certain feed streams.

Here’s a quick look at some factors:

- Product Sensitivity: How much shear can your product tolerate?

- Feed Stream Characteristics: Are there many particulates? Is it viscous?

- Volume Requirements: How much material do you need to process?

- Cleaning Capabilities: Do you need single-use or clean-in-place (CIP) options?

The choice between cassettes and hollow fibers often comes down to a balance of product handling, fouling resistance, and system volume.

c) The Role of Single-Use Systems in Modern Tangential Flow Filtration

Single-use systems are changing the game in many bioprocessing applications, and TFF is no exception. These systems, often made from disposable plastic components, eliminate the need for extensive cleaning and validation between batches. This can significantly speed up process turnaround times and reduce the risk of cross-contamination.

For many companies, especially those dealing with highly potent compounds or requiring rapid process changes, single-use TFF offers a compelling alternative to traditional stainless-steel systems. The initial cost might be higher per use, but the savings in labor, cleaning validation, and downtime can be substantial.

While not all TFF applications are suited for single-use, their adoption is growing. They are particularly attractive for pilot-scale operations and for processes where product purity is paramount. The flexibility they offer in adapting to different process scales and product types is a major advantage. The tangential flow filtration process itself benefits from the reduced operational burden.

Applications and Future Directions in Tangential Flow Filtration

a) Broad Applications of Tangential Flow Filtration in Bioprocessing

Tangential flow filtration, or TFF, is a workhorse in bioprocessing. It’s used for a lot of different things, like concentrating products, swapping out buffers, and cleaning up solutions. Think about making vaccines or gene therapy treatments; TFF is often involved in getting those viral particles ready. It’s also great for isolating tiny things called exosomes, which are important in research and medicine. Basically, if you need to separate molecules based on size or clean up a liquid stream, TFF is probably on the list.

One of the big uses for TFF is in making things like monoclonal antibodies. After you’ve purified the antibody, it’s usually in a big, dilute batch of liquid. TFF can shrink that down to the right concentration and also switch the liquid it’s in to the final buffer needed for the drug. This process, called ultrafiltration and diafiltration (UF/DF), is done all the time in antibody manufacturing. It’s a really efficient way to get the product ready for the next step or for final packaging.

Beyond just concentrating and buffer exchange, TFF also plays a role in harvesting cells and clarifying liquids. Using different types of membranes, TFF can help collect cells from a culture or remove unwanted particles from a liquid. This broad utility makes tangential flow filtration a key technology across many biomanufacturing workflows, from early research to large-scale production.

b) Optimizing Specific Processes with Tangential Flow Filtration

When you’re working with specific biomolecules, you often need to tweak how you use TFF. For instance, if you’re dealing with something fragile, like certain enzymes or viruses, you have to be careful about the shear forces involved. Using hollow fiber modules can be gentler than flat sheet cassettes, which is important for keeping your product intact. The goal is to get the separation you need without damaging what you’re trying to process.

It’s not just about the hardware, though. The settings you use for tangential flow filtration matter a lot. Things like the speed of the flow across the membrane and the pressure pushing liquid through it need to be just right. Getting these parameters dialed in can make a big difference in how much product you recover and how clean it ends up being. It’s a balancing act to maximize yield while minimizing any potential damage to the biomolecules.

Careful selection of membrane type and operating parameters is key to successful tangential flow filtration for sensitive products. Adjusting flow rates and pressures can significantly impact product integrity and process efficiency.

This fine-tuning is what allows TFF to be so versatile. Whether you’re concentrating a protein, purifying a virus, or isolating exosomes, the ability to adjust the process to the specific needs of the product is what makes tangential flow filtration so effective. It’s about making the technology work for the material, not the other way around.

c) The Evolving Landscape of Tangential Flow Filtration Technology

The world of tangential flow filtration is always changing. We’re seeing more automation come into play, which helps make processes more consistent and less prone to human error. Automated systems can monitor and adjust flow rates and pressures in real-time, leading to better results and less downtime. This is a big deal for manufacturing where consistency is everything.

Another area of growth is in single-use systems. These disposable TFF units reduce the need for cleaning and sterilization, which saves time and lowers the risk of contamination. This is especially useful in research labs or for smaller-scale production runs where setting up traditional cleaning cycles might not be practical. The convenience factor is pretty high with these.

Looking ahead, things like digital twins and advanced analytics are starting to show up in TFF. Imagine having a virtual copy of your TFF system that you can use to test out different settings or predict potential problems before they happen. This kind of smart technology promises to make tangential flow filtration even more efficient and reliable in the future, pushing the boundaries of what’s possible in bioprocessing.

Wrapping Up: The Future of TFF is Automated

So, we've talked about how tangential flow filtration, or TFF, is a pretty big deal in making things like medicines. It's a way to clean up and concentrate valuable stuff. But, as we saw, the old ways of doing TFF could be a bit messy, with lots of manual tweaks and inconsistent results. That's where automation comes in. By bringing in smart controls and systems that can adjust on the fly, TFF operations are getting a serious upgrade. This means more reliable processes, less wasted product, and ultimately, a smoother path to getting important therapies to people. It's a big step forward for how we make things in the industry.