A Complete Overview of Laboratory Technology and Equipment

— The equipment choices you make today will impact your operations for years to come.

Setting up or upgrading a laboratory isn't just about buying the fanciest machines you can find. It's about understanding what your facility actually needs to function efficiently, stay compliant, and deliver reliable results. Whether you're launching a biotech startup, expanding a pharmaceutical operation, or modernizing an existing research facility, the equipment choices you make today will impact your operations for years to come.

In this guide, we'll walk through the essential technology and equipment categories every modern laboratory should consider. From environmental controls to analytical instruments, we'll cover what matters most when building a functional, efficient lab space.

Understanding the Foundation of Modern Laboratory Operations

The Role of Technology in Scientific Research

Laboratory technology has come a long way from basic beakers and Bunsen burners. Today's labs are sophisticated operations where automation, digital monitoring, and precision instruments work together seamlessly. This evolution isn't just about being high-tech for its own sake—it directly translates to better accuracy, faster results, and more reproducible research.

Modern laboratories integrate computer systems for data collection, automated processes that reduce human error, and real-time monitoring that alerts staff to potential issues before they become problems. For businesses, this means fewer failed experiments, better quality control, and ultimately, a stronger return on investment.

Core Requirements for Different Laboratory Types

Not all labs are created equal, and your equipment needs will vary significantly based on your focus area. Clinical laboratories prioritize diagnostic accuracy and quick turnaround times. Research and development facilities need flexibility and advanced analytical capabilities. Quality control labs require precise measurement tools and documentation systems. Pharmaceutical and biotech operations must maintain strict environmental controls and meet regulatory standards.

Understanding where your laboratory fits in this spectrum is the first step toward making smart equipment decisions. A startup biotech company has very different needs than an established hospital laboratory, and your equipment list should reflect those unique requirements.

Environmental Control and Monitoring Systems

Temperature and Atmosphere Management

Here's something many lab managers learn the hard way: environmental conditions can make or break your experiments. Cell cultures, tissue samples, and biological materials are incredibly sensitive to temperature fluctuations, humidity changes, and atmospheric composition. Even small variations can compromise months of work.

That's where precise environmental control becomes non-negotiable. For cell culture work and biotechnology applications, specialized equipment provides the exact conditions your samples need to thrive. A co2 incubator maintains specific temperature, humidity, and carbon dioxide levels essential for growing cells and tissues. These units often include features like contamination prevention systems, uniform temperature distribution, and digital monitoring that lets you track conditions remotely.

Beyond incubation equipment, comprehensive climate control includes refrigeration systems, freezers for long-term storage, temperature-controlled rooms, and automated monitoring systems that alert staff immediately if conditions drift outside acceptable ranges. Think of these as insurance policies for your valuable samples and experiments.

Contamination Prevention Technologies

Contamination is every laboratory's worst nightmare. One airborne particle in the wrong place can invalidate entire batches of work. That's why modern labs invest heavily in contamination prevention, starting with robust air filtration and purification systems.

HEPA filters remove microscopic particles from the air. Biological safety cabinets protect both samples and personnel. Cleanroom equipment maintains particle-free environments for sensitive procedures. UV sterilization systems add an extra layer of protection. Together, these technologies create multiple barriers against contamination, giving you peace of mind that your results are accurate and your team is safe.

Analytical and Testing Equipment

Measurement and Analysis Tools

The heart of any laboratory is its analytical equipment. These are the tools that help you understand what's really happening at the molecular level. Spectroscopy equipment analyzes how substances interact with light, revealing chemical composition and concentration. Chromatography systems separate complex mixtures into individual components for detailed analysis.

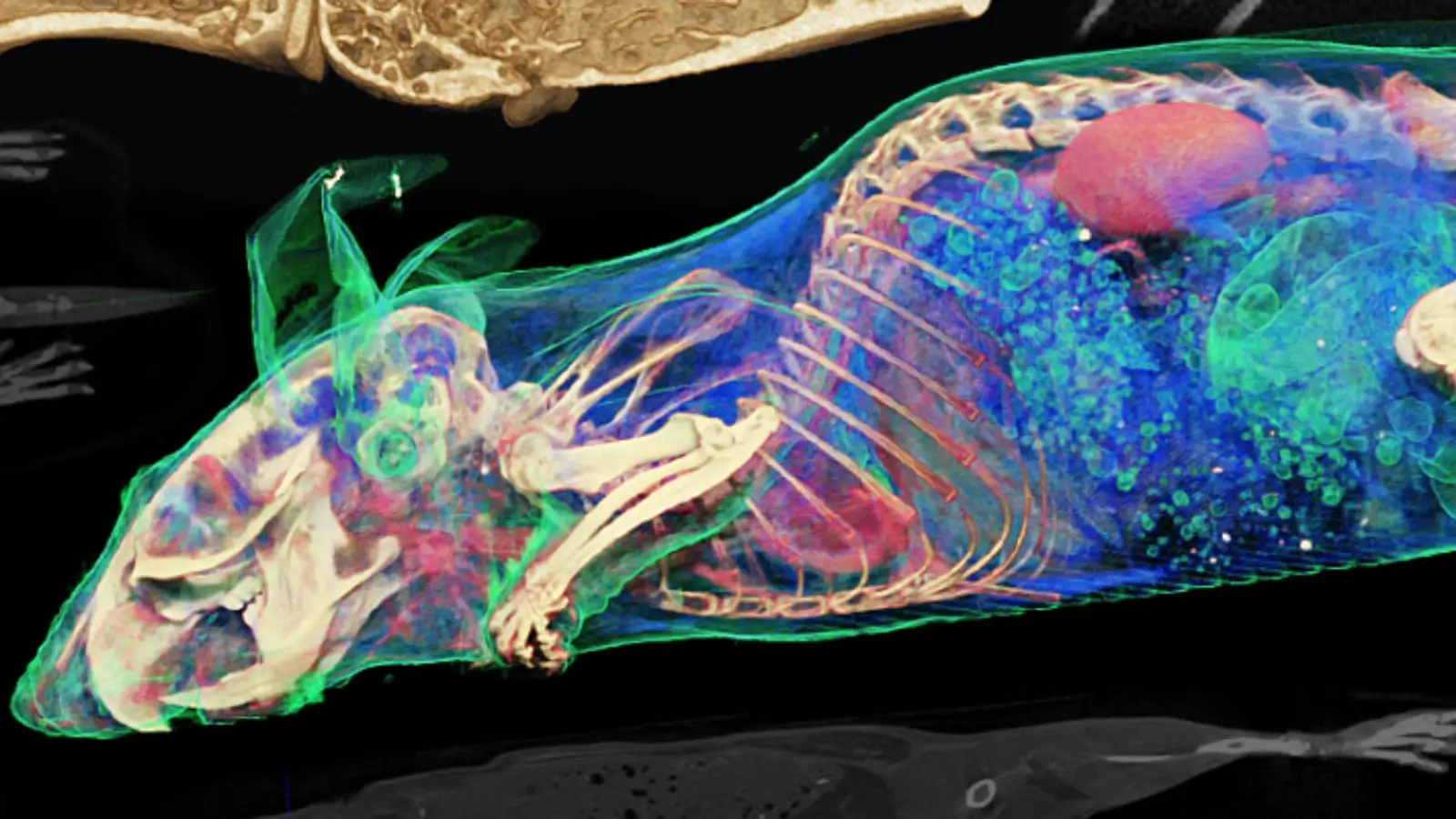

Microscopy has evolved far beyond simple optical instruments. Today's microscopes use electron beams, fluorescence, and confocal technology to visualize structures at incredibly small scales. Mass spectrometry combines separation and detection to identify unknown compounds with remarkable precision. While these instruments represent significant investments, they're often essential for cutting-edge research and quality assurance.

Sample Preparation and Processing

Before you can analyze samples, you need to prepare them properly. This is where workhorses like centrifuges, homogenizers, and automated liquid handling systems come in. Centrifuges separate materials by density—think of them as super-powerful spinning machines that can isolate specific components from complex mixtures.

Homogenizers break down samples into uniform consistencies for more accurate testing. Automated liquid handling systems reduce human error in pipetting and dilution, especially crucial when working with expensive reagents or running hundreds of samples. And don't overlook storage solutions—proper sample preservation, whether at room temperature, refrigerated, or frozen, protects your materials until you're ready to analyze them.

Safety and Compliance Infrastructure

Personal Protection and Lab Safety Equipment

Safety isn't optional in laboratory settings—it's fundamental. Fume hoods protect personnel from harmful vapors and gases, pulling contaminated air away from breathing zones and filtering it before release. Chemical storage cabinets prevent dangerous reactions and contain spills. Emergency equipment like eyewash stations and safety showers provide immediate response capability when accidents occur.

Proper ventilation systems maintain air quality throughout the facility, while personal protective equipment—gloves, lab coats, goggles, and respirators—create the last line of defense for your team. Investing in comprehensive safety infrastructure protects your most valuable asset: your people.

Regulatory Compliance Considerations

Operating a laboratory means navigating a complex web of regulations. Industry standards vary by sector, but most labs must maintain detailed documentation of procedures, equipment calibration, and maintenance activities. Regular inspections, quality management systems, and standard operating procedures aren't just bureaucratic hurdles—they're frameworks that ensure consistent, reliable results.

Compliance also extends to equipment certification, operator training requirements, and environmental monitoring. Working with equipment suppliers who understand regulatory requirements can simplify this process considerably, ensuring your purchases meet necessary standards from day one.

Procurement and Investment Strategies

Evaluating Equipment Needs

Before writing any checks, take a step back and assess what you actually need. Start with your research or business objectives. What experiments or tests will you run most frequently? What's your expected sample volume? How might your needs evolve over the next few years?

Consider practical factors too: available space, utility requirements like electrical capacity and water supply, and budget constraints. It's tempting to want the latest, greatest equipment, but the best choice is often the one that reliably meets your needs without breaking the bank.

Making Smart Purchase Decisions

When it comes to procurement, you've got options. New equipment offers warranties, the latest features, and peace of mind. Refurbished equipment can deliver significant cost savings while still providing reliable performance—just ensure it comes from reputable suppliers with proper certification.

Leasing versus buying is another key decision. Leasing preserves capital and includes maintenance, but buying may cost less long-term. Evaluate suppliers carefully: look for responsive customer service, comprehensive training programs, and reliable technical support. The cheapest option upfront isn't always the smartest choice when you factor in the total cost of ownership, including maintenance, consumables, and eventual replacement.

Maintenance and Operational Excellence

Preventive Maintenance Programs

Equipment only performs well when it's properly maintained. Establish routine calibration schedules—most precision instruments require regular verification to ensure accuracy. Track equipment performance over time to identify potential issues before they cause failures.

Training staff on proper usage extends equipment life and prevents costly mistakes. Create clear standard operating procedures for each instrument, and make sure everyone follows them. When problems do arise, having troubleshooting guides and good supplier relationships speeds resolution dramatically.

Optimizing Laboratory Efficiency

Beyond individual equipment maintenance, think about your laboratory as an integrated system. Workflow optimization means arranging equipment logically, minimizing sample transport time, and reducing bottlenecks. Laboratory information management systems (LIMS) track samples, manage data, and maintain audit trails automatically.

Consider energy efficiency too—modern equipment often uses less power while delivering better performance. Look for Energy Star ratings and consider the environmental impact of your choices. Sustainable laboratory operations aren't just good for the planet; they often reduce operating costs too.

Conclusion

Building an effective laboratory requires careful planning, smart investments, and ongoing attention to maintenance and optimization. The equipment landscape can seem overwhelming, but by focusing on your specific needs, prioritizing safety and compliance, and thinking long-term about total cost of ownership, you can create a facility that delivers reliable results for years to come.

Remember, the goal isn't to have the most impressive equipment roster—it's to have the right tools for your specific applications. Start with essentials, plan for growth, and don't hesitate to seek expert advice when making major purchases. Your laboratory is the foundation of your research or business success, and the equipment choices you make today will shape your capabilities tomorrow.

FAQs

What factors should be considered when selecting laboratory equipment?

Focus on your specific application requirements first, then consider factors like available space, budget constraints, compliance needs, and potential for future growth. Don't forget to evaluate the supplier's reputation, technical support availability, and training programs. Total cost of ownership—including maintenance, consumables, and energy use—often matters more than initial purchase price.

How often should laboratory equipment be calibrated and maintained?

Calibration schedules vary by equipment type and regulatory requirements. Precision instruments like balances and pH meters typically need monthly or quarterly calibration. More stable equipment might require only annual verification. Always follow manufacturer recommendations and regulatory requirements for your specific industry. Keep detailed maintenance logs—they're essential for compliance and help predict when equipment might need replacement.

What is the typical lifespan of major laboratory equipment?

Quality laboratory equipment generally lasts ten to fifteen years with proper maintenance, though this varies significantly. Analytical instruments like spectrophotometers might last fifteen to twenty years. Refrigeration units typically run ten to fifteen years. Computers and software need updating every three to five years. Regular maintenance, careful handling, and staying current with software updates can extend equipment life considerably.

Should businesses buy or lease laboratory equipment?

It depends on your situation. Buying makes sense if you have the capital, plan to use the equipment long-term, and want to build equity. Leasing preserves cash flow, includes maintenance and upgrades, and offers flexibility—ideal for startups or rapidly evolving research programs. Consider leasing for technology that evolves quickly, buying for stable, long-term equipment needs. Many labs use a hybrid approach, buying core equipment while leasing specialized or frequently updated instruments.