Preparing test specimens has always been a demanding step in materials testing. Tensile and impact samples form the backbone of mechanical evaluation, yet the process of getting them ready has traditionally been slow and resource-heavy.

For most engineers and quality teams, this has meant operating separate machines, switching between setups, and spending extra hours to confirm consistency. What looks like a routine step on paper often turns into one of the most time-consuming stages of the entire testing cycle.

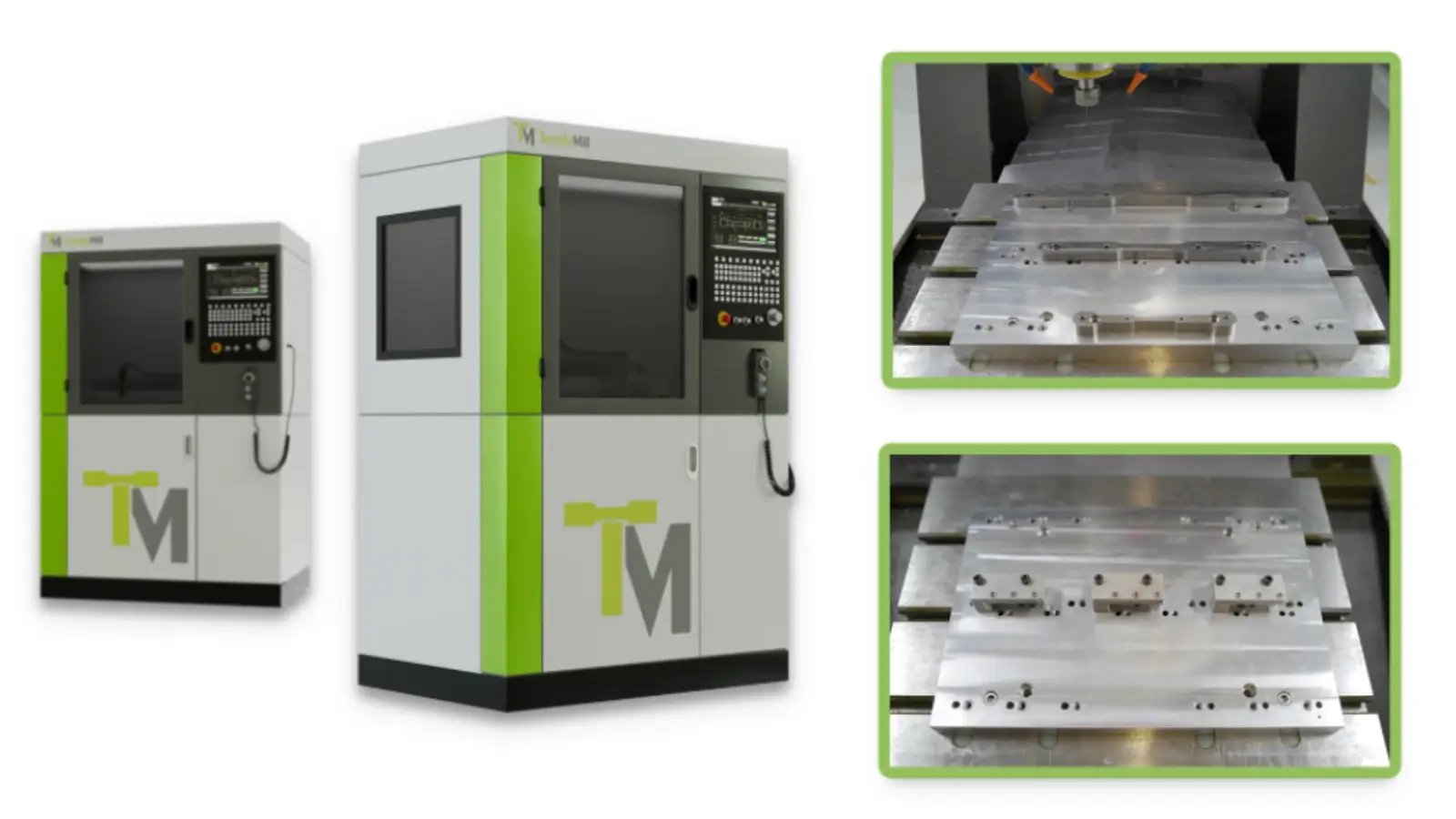

With the introduction of hybrid CNC systems such as the TensileMill CNC – Classic Upgrade, this familiar picture is starting to change. For the first time, a single platform allows both tensile and impact specimen preparation, and this shift is drawing attention across laboratories and production floors.

For decades, the routine has been predictable: laboratories relied on separate specimen preparation machines for tensile testing, while using additional systems for impact specimens. On paper, this division seemed practical, as each testing method required its own geometry and tolerances. In reality, it meant laboratories had to maintain two sets of equipment, train operators twice, and dedicate extra space to machines that rarely spoke the same language. Even in large facilities, the duplication of resources created inefficiencies that engineers simply accepted as the cost of doing business.

The challenges went deeper than logistics. Every time a sample was moved from one preparation setup to another, there was the risk of inconsistency. Small deviations in geometry, surface finish, or notch quality could undermine test results. Standards such as ASTM E8 for tensile testing or ASTM E23 for impact testing leave little room for error, and laboratories had to spend extra hours verifying compliance. In environments where production schedules are tight and client audits frequent, this was a source of constant pressure.

Another problem was the reliance on skilled operators. While experienced machinists could achieve remarkable precision, training new staff to handle two separate specimen preparation workflows was time-consuming. In many companies, this created a gap: either overwork the experts or accept a learning curve that slowed down throughput. Smaller organizations, without the budget for duplicate machines or extensive staff training, faced even greater barriers.

These realities made specimen preparation one of the most time-consuming stages of the testing cycle. Engineers often describe it as the hidden bottleneck, an area that does not directly generate data but heavily influences its quality. Without consistent preparation, tensile curves or impact values lose credibility, and projects can stall. The industry has long searched for a way to unify the process, reduce errors, and bring efficiency to this overlooked stage. The emergence of hybrid CNC systems, combining tensile and impact workflows under one roof, is a direct response to these long-standing frustrations.

The TensileMill CNC – Classic Upgrade represents the first widely recognized attempt to merge tensile and impact specimen preparation into a single CNC platform. Rather than splitting the process into two parallel workflows, the machine brings them together through a unified setup. For laboratories and production facilities, this means that specimens for tensile testing and those for impact analysis can be produced with the same clamping system, control software, and operator interface.

At the core of this hybrid approach is the integration of a FANUC controller with proprietary TensileSoft software. Operators can select preprogrammed specimen geometries that align with ASTM, ISO, DIN, and JIS standards, or they can create their own custom parameters. This flexibility allows research groups to prepare experimental samples without leaving the same machine that handles day-to-day compliance work. By reducing transitions, the Classic Upgrade effectively shortens preparation times and lowers the chance of misalignment.

Another defining element is its ability to support impact notching through an optional attachment. By pairing the system with an automated notching module, laboratories can prepare U-notch and V-notch impact samples directly, without switching to a separate piece of equipment. This combination is especially relevant for teams that must frequently alternate between tensile elongation studies and impact toughness checks. Instead of scheduling multiple setups across different machines, the workflow now follows a straight line: one system, one interface, two categories of specimens.

Hybrid design is valuable only if it does not compromise accuracy. The TensileMill CNC – Classic Upgrade has been engineered with this concern in mind, and its performance benchmarks reflect the priorities of today’s quality control environment. Positioning precision reaches fractions of a millimeter, while repeatability remains consistent across multiple batches of specimens. For companies that handle dozens of samples in a single day, this level of control is critical to maintaining confidence in test data.

Surface finish is another area where the system demonstrates stability. Meeting surface roughness requirements below 75Ra ensures that tensile and impact specimens are free from defects that could skew results. In tensile testing, even minor scratches can act as premature fracture points, while in impact testing, surface irregularities can mask true material behavior. By holding a uniform finish, the Classic Upgrade removes a frequent source of uncertainty from test preparation.

Compliance with international standards is embedded into the workflow. ASTM E8 tensile specimens and ASTM E23 impact specimens can be machined directly, along with ISO 75 or DIN geometries, depending on the project’s requirements. The library of preprogrammed shapes minimizes operator error and provides a traceable link between preparation and testing. For laboratories facing regular audits or client inspections, this built-in compliance reduces the administrative burden that often comes with specimen preparation.

Equally important is the documentation of repeatability. By producing multiple specimens with identical geometry, laboratories can verify results without worrying that variation stems from inconsistent preparation. This strengthens both the reliability of testing and the confidence of stakeholders who depend on that data for design or certification decisions.

Beyond accuracy and compliance, the TensileMill CNC – Classic Upgrade addresses the practical concerns that often weigh most heavily on production teams. Time, training, and space are resources that laboratories and factories cannot afford to waste, and this hybrid CNC system introduces measurable improvements in all three areas.

Throughput is the most visible advantage. The system can prepare up to eight specimens simultaneously, cutting preparation time by as much as 90 percent compared to traditional methods. For busy facilities, this means faster turnaround between receiving raw material and delivering mechanical test data. The consistency of preparation also reduces the need for repeat machining, further accelerating workflows.

Operator training has historically been a major cost in specimen preparation. Teaching staff to handle multiple machines, each with different controls, requires weeks of practice and often ties up experienced machinists in supervisory roles. With the Classic Upgrade, operators—whether novices or seasoned technicians—work with a single software environment. Preloaded standards and intuitive controls shorten the learning curve, allowing new staff to contribute productively in less time.

Space efficiency also matters in laboratories where every square foot is accounted for. Housing separate tensile and impact preparation equipment not only consumes more floor area but also complicates layout planning. By combining both functions, the Classic Upgrade reduces equipment redundancy and simplifies facility design. This consolidation is particularly relevant for organizations aiming to modernize their labs without expanding their footprint.

Together, these operational gains highlight the broader role of hybrid CNC systems: they do not just refine specimen preparation but reshape how teams allocate their most limited resources.

The arrival of hybrid CNC systems like the TensileMill CNC – Classic Upgrade signals more than just an incremental upgrade in equipment. It reflects a shift in how laboratories and production facilities view the process of preparing tensile and impact specimens. What was once a split workflow is becoming unified, predictable, and far easier to manage.

For quality assurance teams, this means greater confidence that test data is supported by consistently prepared specimens. For engineers and production managers, it offers a way to streamline operations without sacrificing compliance with ASTM, ISO, or DIN standards. And for organizations under pressure to deliver results quickly, the efficiency gains provide a competitive edge in industries where delays translate into higher costs.

The significance of this development lies in its ability to balance precision with practicality. Hybrid CNC systems are not just about sharper tolerances or faster cycle times—they are about making specimen preparation an integrated part of the testing process, rather than a recurring obstacle. By reducing errors, consolidating equipment, and improving repeatability, they lay the groundwork for a new standard in materials testing.

As more facilities adopt this type of solution, the conversation around specimen preparation is likely to change. Instead of being seen as a bottleneck, it may become one of the most reliable and transparent stages of the entire testing cycle. The Classic Upgrade is one of the first examples of this change in action, and its presence marks an important step toward the future of testing.