Electric motors are the silent workhorses that drive modern machines from industrial systems to home appliances. Behind their smooth performance lies an intricate combination of engineering precision and mechanical balance. These qualities determine how efficiently a motor runs, how long it lasts, and how much energy it consumes.

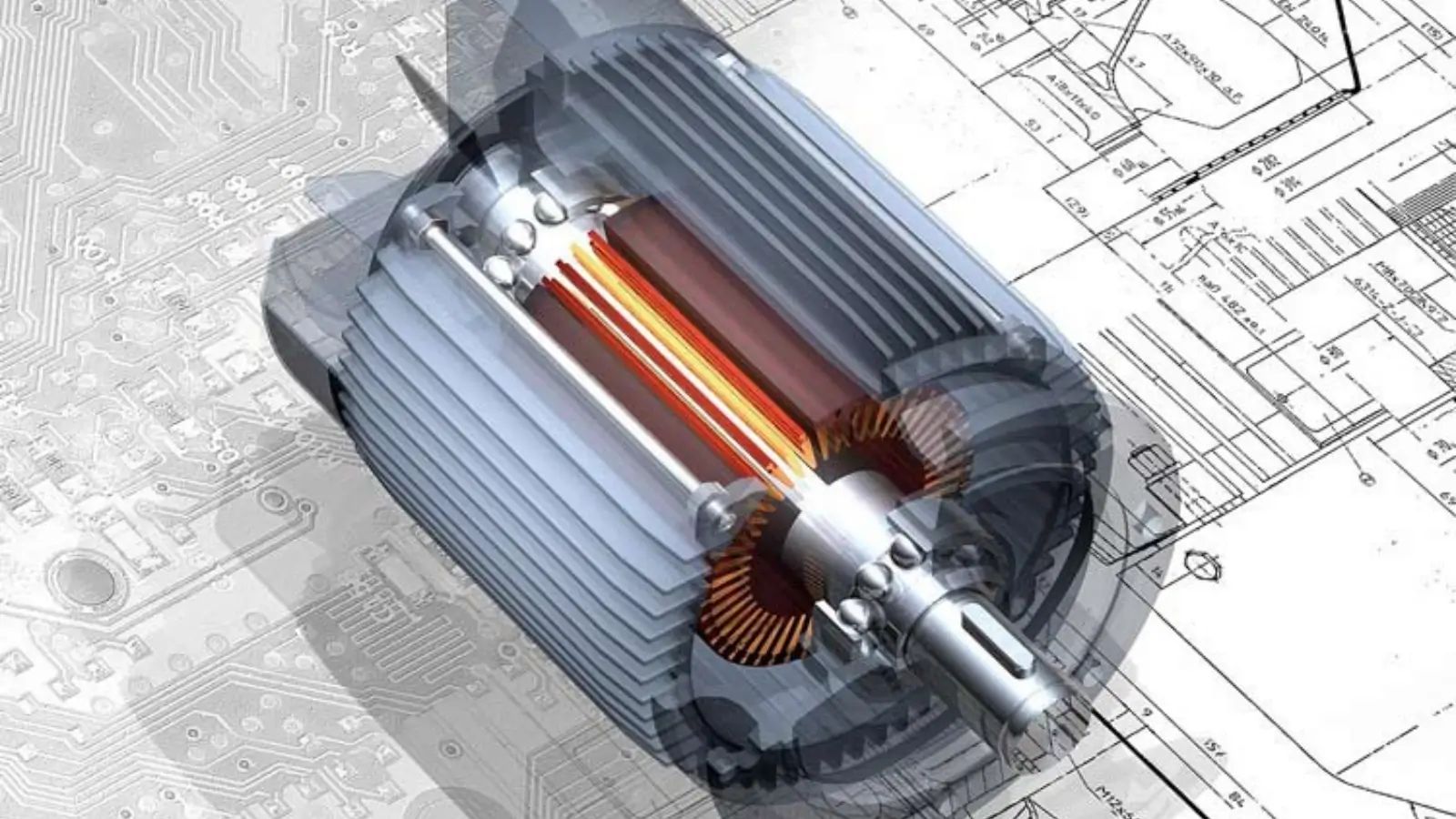

At the heart of every motor lies the electric motor rotor and stator, two components that must operate in perfect harmony. Their alignment and balance ensure consistent power output and prevent vibration or wear. Learning why precision and balance matter provides valuable insight into what makes modern motors powerful, reliable, and efficient.

Precise alignment ensures that every moving part interacts correctly within the motor. When components like the rotor and shaft align properly, friction remains minimal and energy conversion remains efficient. Even minor misalignment can cause vibration, noise, or power loss.

Engineers in motor design carefully calculate tolerances to maintain perfect positioning. Proper alignment also prevents uneven wear on bearings and other parts, which extends operational life. Without precision, energy loss increases, leading to reduced performance and higher maintenance costs.

The relationship between the rotor and stator defines how electric motors generate motion. The rotor moves within the stationary stator, creating a magnetic field that produces torque. This interaction must remain balanced to maintain efficiency and prevent overheating.

When gaps between the two are consistent, energy transfer remains smooth. However, uneven spacing disrupts magnetic fields and reduces output. Precision ensures that the electric motor rotor and stator function as a synchronized unit, maintaining steady rotation and reliable performance under varying loads.

A perfectly balanced motor converts electrical energy into motion with minimal waste. Imbalance causes vibration, which leads to heat buildup and increased power consumption. Over time, this lowers efficiency and weakens structural integrity.

Motor balance involves distributing weight evenly across all rotating parts. Engineers use dynamic balancing techniques to detect and correct even the slightest irregularities. The result is a motor that runs smoothly, quietly, and with optimal energy efficiency.

Modern motor production relies on advanced manufacturing technology to achieve exact dimensions. Components are cut, machined, and assembled with microscopic accuracy. Any variation can affect performance or cause early component failure.

Computer-controlled systems and laser-guided tools ensure every piece fits perfectly within its housing. This precision minimizes vibration, reduces friction, and ensures reliable operation across different speeds. Manufacturers maintain strict quality control to meet performance standards and safety regulations.

The choice of materials directly affects balance and durability. Lightweight yet strong materials help minimize stress on moving parts while maintaining stability. Engineers often use specialized alloys and laminated steel for improved magnetic efficiency.

Each material is selected for its specific role from the rotor’s core to the stator’s winding insulation. Proper material pairing prevents energy loss and heat damage, contributing to better overall balance. Precision in material selection supports the motor’s ability to handle high speeds without distortion.

Vibration is one of the most common issues in motor performance. It leads to noise, friction, and fatigue in internal parts. Precision engineering ensures that all components remain stable under varying loads and speeds.

Dynamic balancing systems are used to measure and correct imbalance during assembly. Additional dampening techniques help absorb minor vibrations before they affect other parts. Reduced vibration results in a quieter, longer-lasting motor that operates smoothly even under heavy use.

Before motors reach the market, they undergo extensive testing to verify performance accuracy. Calibration ensures that torque, speed, and energy output remain consistent across operating conditions. These tests detect even minor imperfections that could lead to imbalance or inefficiency.

Advanced diagnostic tools help manufacturers fine-tune each unit. Regular recalibration during service intervals also helps maintain performance over time. Precision testing guarantees that motors meet the demanding standards of industrial, automotive, and commercial applications.

Even the most advanced motors require upkeep to retain their original balance. Routine maintenance includes inspecting bearings, alignment, and electrical connections. Lubrication and vibration checks also play a key role in preventing degradation.

Service teams rely on diagnostic equipment to detect small shifts that affect performance. Early intervention avoids breakdowns and costly repairs. Regular maintenance ensures that the motor continues to run efficiently and quietly, even after years of operation.

Key factors that contribute to precision and balance include:

Attention to these details ensures reliable performance and extended operational life.

Precision and balance lie at the core of motor performance. Every detail, from material selection to dynamic balancing, influences how smoothly the machine runs. The partnership between the electric motor rotor and stator demonstrates how careful engineering creates power through harmony.

When designed, tested, and maintained with accuracy, motors deliver efficiency, longevity, and stability. This balance of precision and craftsmanship ensures the reliable performance that industries and consumers depend on every day.