There was a time when manufacturing felt out of reach for smaller companies. Big factories, huge budgets, and long production cycles created an uneven playing field that left startups and small businesses struggling to compete. But things have changed. On-demand manufacturing has made it possible for small teams to design, test, and produce products without massive overhead or long delays. Whether it’s a local entrepreneur launching a new gadget or a small furniture brand refining its designs, these businesses are finding new ways to bring ideas to life faster and more affordably.

Today’s market moves quickly, and being able to pivot is everything. Traditional manufacturing often locks businesses into big orders, high costs, and long waiting periods. For smaller companies, that can be a deal-breaker. On-demand manufacturing flips the script by letting them produce exactly what they need, when they need it. There’s no need to stockpile inventory or gamble on what might sell months from now. Instead, businesses can test ideas, gather real feedback, and scale only when it makes sense. It’s a more efficient, less risky way to grow.

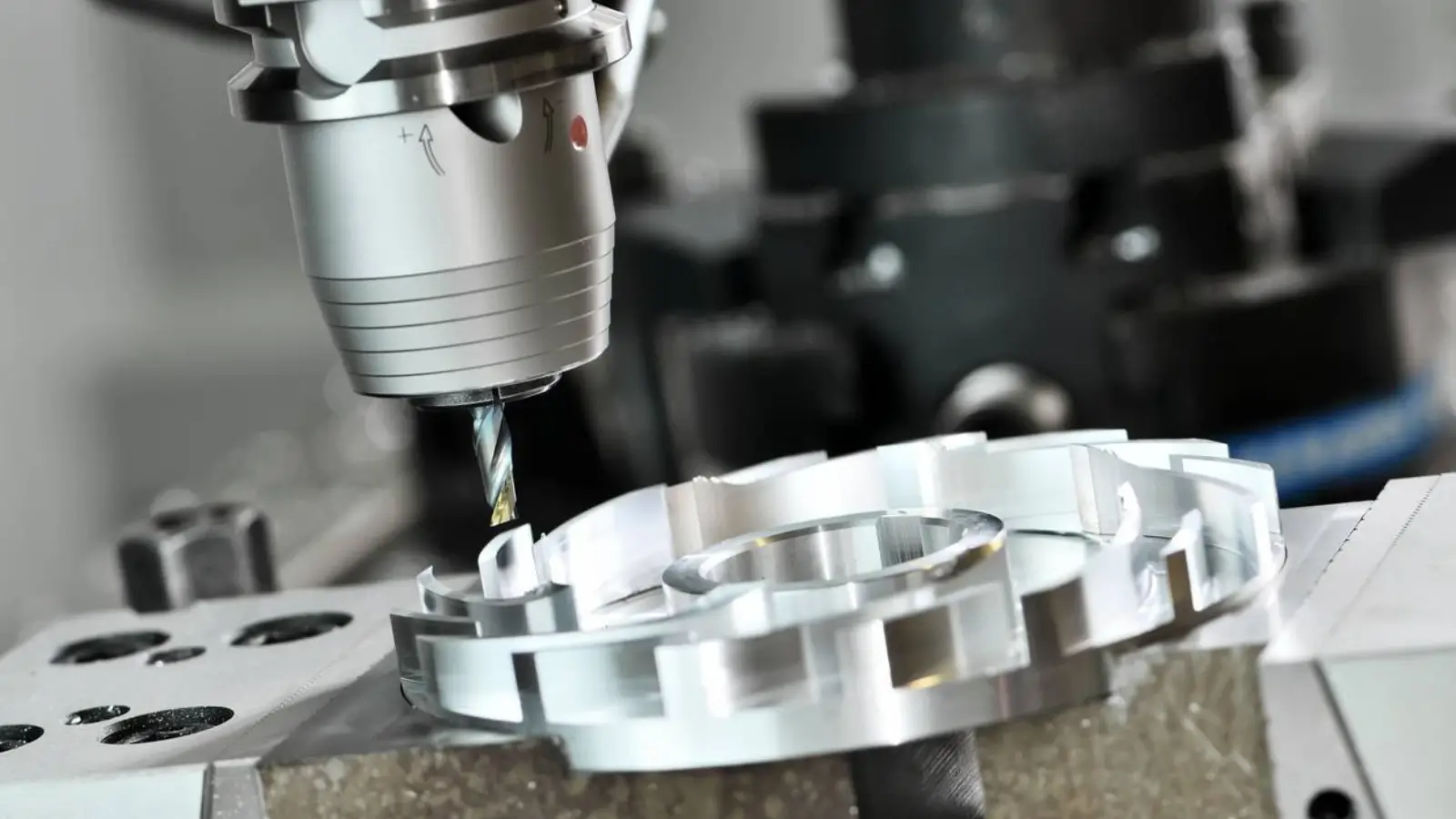

The rise of digital tools has completely changed what’s possible. Services like 3D printing, laser cutting, and CNC machining have made professional-quality production available to anyone with a solid design. A small business can now send off a file and get precision parts delivered in days instead of months. For example, a single CNC machining service can produce high-quality metal components that used to require large factory contracts. This kind of access empowers small businesses to prototype, refine, and launch without needing to own expensive machinery or hire a full production team.

For small companies, developing a prototype used to mean spending thousands of dollars and waiting weeks to see results. If something went wrong, it meant starting over, and starting over wasn’t cheap. On-demand manufacturing has made that process easier and more forgiving. With technologies like 3D printing, a business can create a prototype quickly, test it, make improvements, and try again, often in the same week. It encourages experimentation and allows for real-world testing before big production investments are made.

Another major benefit is sustainability. Instead of overproducing items that might never sell, on-demand manufacturing allows businesses to make only what’s needed. Less waste means less cost and a smaller environmental footprint. Techniques like 3D printing use materials more efficiently, building products layer by layer rather than cutting away excess. For many small companies, this approach feels like the best of both worlds: responsible production that doesn’t slow down innovation.

Small businesses often win by offering something personal or unique. On-demand manufacturing gives them the tools to make that happen at scale. Laser cutting, for instance, allows for intricate designs and customized features that appeal to modern consumers who want something that feels one-of-a-kind. The ability to collaborate with specialized manufacturing partners and deliver customized products gives small brands a creative edge that larger competitors can’t always match.

What’s happening now in manufacturing is more than a passing trend; it’s a power shift. As technology continues to advance and become even more accessible, small businesses will keep finding new ways to innovate. They’re proving that you don’t need a massive factory or corporate budget to create something great. You just need the right tools, a good idea, and the willingness to adapt.

On-demand manufacturing has turned what used to be a complicated process into something approachable and exciting. It gives small businesses the ability to move faster, stay flexible, and bring new products to life with confidence. With 3D printing, laser cutting, and other modern production tools at their fingertips, small companies are no longer playing catch-up. They’re leading the charge in creativity and innovation.