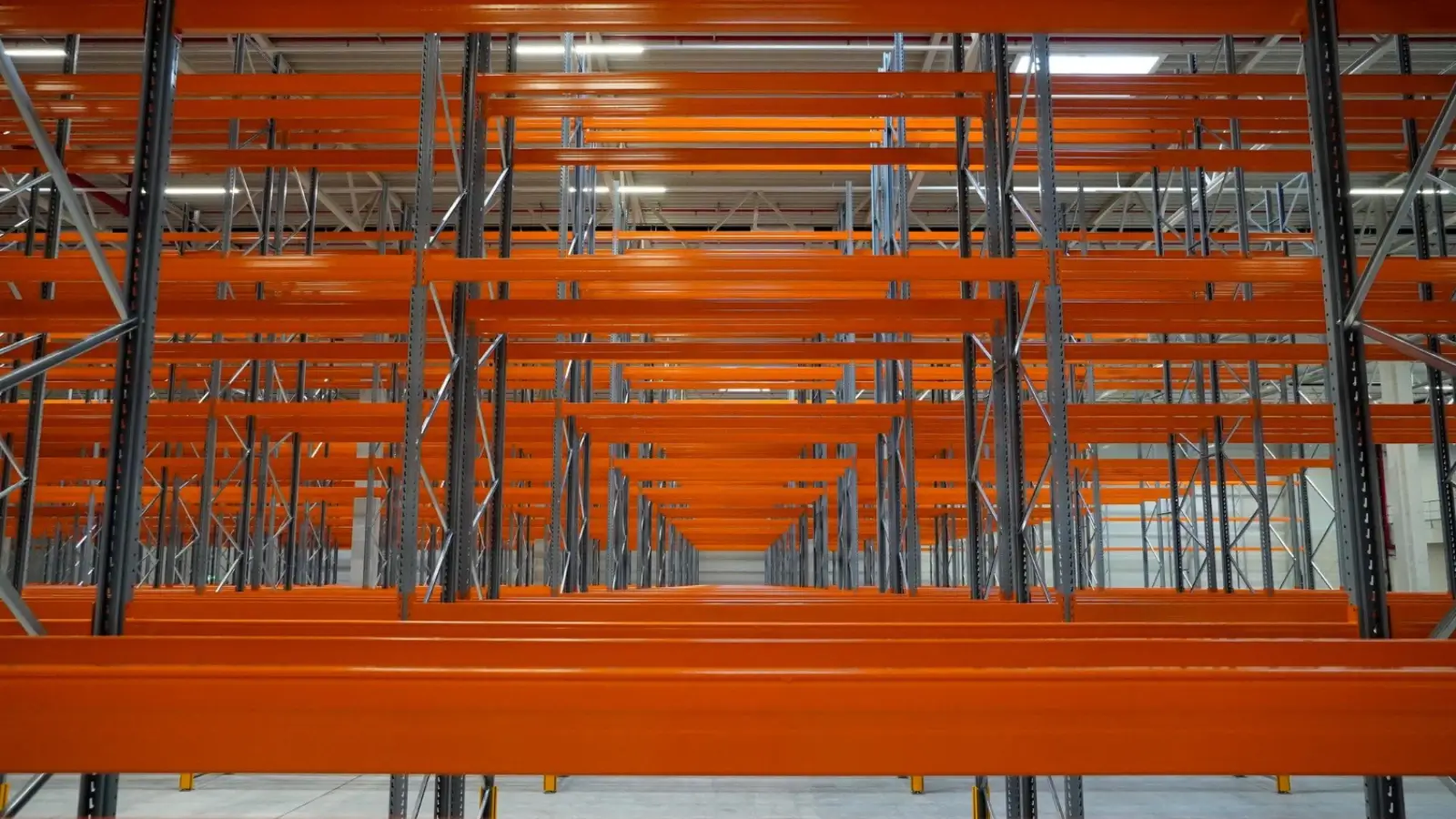

Warehouse efficiency depends on choosing storage systems that match your inventory characteristics and operational workflow. Cantilever racking provides a specialized solution for materials that don't fit standard pallet configurations, offering unobstructed access and flexible configuration options. These systems are engineered to handle loads ranging from lightweight plastic pipes to multi-ton steel coils, with proper design capable of supporting 20,000kg or more per column. Understanding how these systems function and integrate into warehouse operations is essential for maximizing storage density while maintaining safe, efficient material handling.

Core Components and Structure

A cantilever system consists of four main elements. The base provides stability and distributes weight to the floor. Vertical columns (uprights) bolt to the base and extend upward to create storage height. Horizontal arms attach to the columns at adjustable intervals, and these actually support your products. Bracing connects everything together, typically in an X pattern across the back for single-sided units or through horizontal ties for double-sided configurations.

The engineering here matters more than people realize. Arm length, column spacing, and base depth all get calculated based on load characteristics. An improperly specified system might look fine but could fail under full capacity, which is obviously something you want to avoid.

Load Capacity Considerations

Not all cantilever systems are created equal. Light-duty systems handle up to 500kg per arm and work fine for items like plastic piping, carpet rolls, or aluminum extrusions. Medium-duty setups support 500-1500kg per arm, suitable for timber products and bundled materials. Heavy-duty industrial systems can manage 2000kg or more per arm for steel products, machinery components, and dense materials.

The load rating accounts for weight distribution along the arm length. A 1000kg capacity doesn't mean you can put 1000kg at the very end of the arm. Concentrated loads at the tip create more stress than distributed loads along the arm's length. Manufacturers provide load charts that specify capacity at different positions.

Configuration Flexibility

One of the biggest advantages is how adaptable these systems are. You can adjust arm positions vertically without major disassembly, usually just requiring a forklift and some basic tools. This lets you reconfigure storage as inventory changes, which is huge for businesses with seasonal product variations or evolving product lines.

Column spacing (the distance between uprights) typically ranges from 1.5 to 3 meters, depending on load length and weight. Closer spacing provides more support for heavy items, while wider spacing maximizes storage capacity for lighter, longer materials. Some operations use variable spacing within the same system to accommodate different product types in adjacent bays.

Integration with Material Handling

The system needs to work with your existing forklifts and handling equipment. Reach trucks, counterbalance forklifts, and side loaders all interact with cantilever racking differently. Aisle width requirements vary based on the equipment you're using and the length of materials being handled.

For optimal efficiency, many warehouses set up their cantilever systems perpendicular to main traffic aisles. This allows forklifts to approach straight on, reducing maneuvering time and improving safety.