When planning a construction, renovation, or industrial project, choosing the right material is key. One option that combines durability, corrosion resistance, and a non-slip surface is Stainless Steel Diamond Plate. Whether you’re outfitting a workshop, upgrading a commercial kitchen, or building a trailer floor, understanding this material helps you make a smart buying decision.

Stainless steel is a metal alloy made mainly of iron, with added chromium and other elements to make it resistant to rust and corrosion. It’s widely used in industries like construction, food processing, and manufacturing.

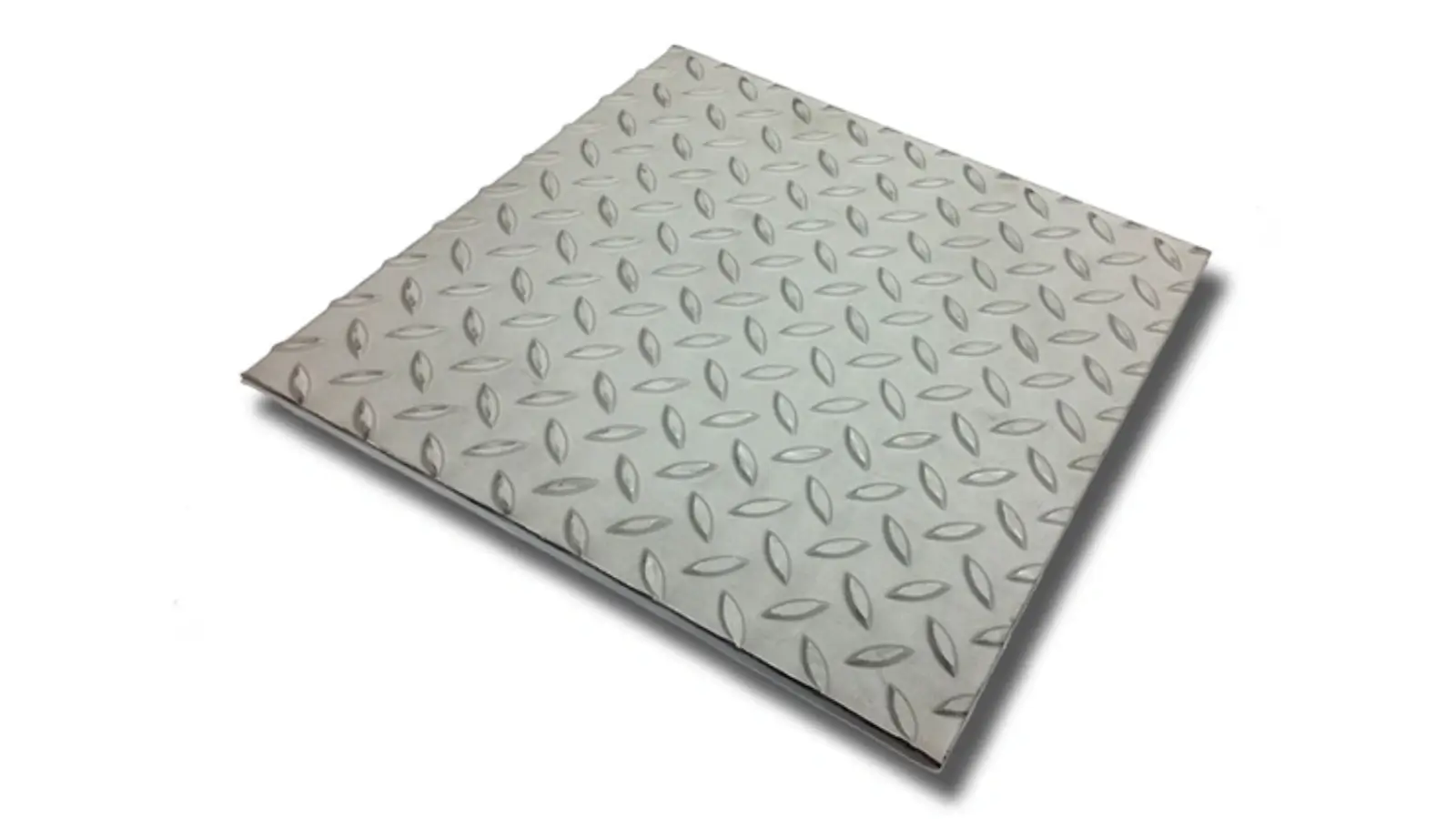

Diamond plate, also known as checker plate or tread plate, is a metal sheet with a raised diamond pattern on one side. The texture improves traction, making it a popular choice for flooring, stairs, and industrial surfaces.

Diamond plate can be made from aluminum, steel, or stainless steel. If you're looking for both durability and corrosion resistance, stainless steel diamond plate is the best option.

Choosing between stainless steel and diamond plate depends on your project needs.

When shopping for stainless steel or diamond plate, consider the following:

Make sure you’re buying the correct grade for your application. For example, 316 is better for saltwater environments, while 304 is fine for indoor or light outdoor use.

Check the gauge or thickness of the material. Thicker metal means more strength but also more weight and cost. For flooring or heavy-duty use, a thicker plate is recommended.

Stainless steel comes in various finishes like brushed, mirror, or matte. Choose a finish based on both appearance and function (e.g., brushed is less reflective and shows fewer fingerprints).

Diamond plate also comes in polished or dull finishes depending on the application.

Measure your project area and choose sheet sizes that minimize cutting and waste. Standard sizes are often 4’x8’ or 5’x10’, but custom sizes may be available.

If you need to bend, cut, or weld the metal, make sure the type and grade you choose supports fabrication.

Higher grades like 316 stainless steel cost more, but they last longer and perform better in harsh environments. Consider long-term value, not just upfront price.

Here are some popular uses for stainless steel and diamond plate:

Both materials are low maintenance, but here’s how to keep them in top shape:

Stainless steel and diamond plate are durable, reliable, and versatile materials suitable for a wide range of projects. Whether you’re upgrading your workshop, building a commercial kitchen, or reinforcing industrial flooring, choosing the right type and grade of material is essential.

Before buying, consider where and how the material will be used, what level of corrosion resistance is needed, and what kind of look and texture you prefer. With the right choice, you’ll invest in materials that perform well for years to come.