Today's fast-changing industrial scene calls on accuracy and efficiency as key elements of technological advancement. From robotics to biomedical equipment, every industry relies on motion—controlled, repeatable, and extremely accurate motion to guarantee dependable performance. Innovations in smart actuation, sensors, and control systems are changing our approach to machine design and operation, therefore opening up fresh opportunities for creativity across several sectors.

Simple mechanical drives are not anymore depended upon by contemporary companies. They instead include intelligent systems able to adjust to difficult operating situations. Mechanical engineering interacts with electronics, computer science, and materials science through these technologies to provide unmatched precision and responsiveness.

Between accuracy and flexibility, classic systems often had trade-offs. New generations of actuators and controllers, sometimes influenced by biological systems, enable exact movement on nanoscale level, nevertheless. This development has enabled the automation of delicate operations including chip assembly, biological cell manipulation, or component alignment in scientific equipment.

Precision is the capacity to consistently duplicate movements without variation, not only correctness. In semiconductor manufacturing, even a small mistake of a few nanometers can result in flawed goods. Similarly, in surgical robotics, a little misalignment might change the result of a surgery.

The need for ultral-precise placement grows as companies embrace smaller, more integrated designs. Systems have to not just reach this accuracy but keep it over time despite wear, temperature fluctuations, and environmental variables, including vibrations.

Every precision device centers around a complex control system. While constantly monitoring sensor feedback, controllers convert input commands into mechanical movements. These feedback systems guarantee accurate, steady, and flawless operation.

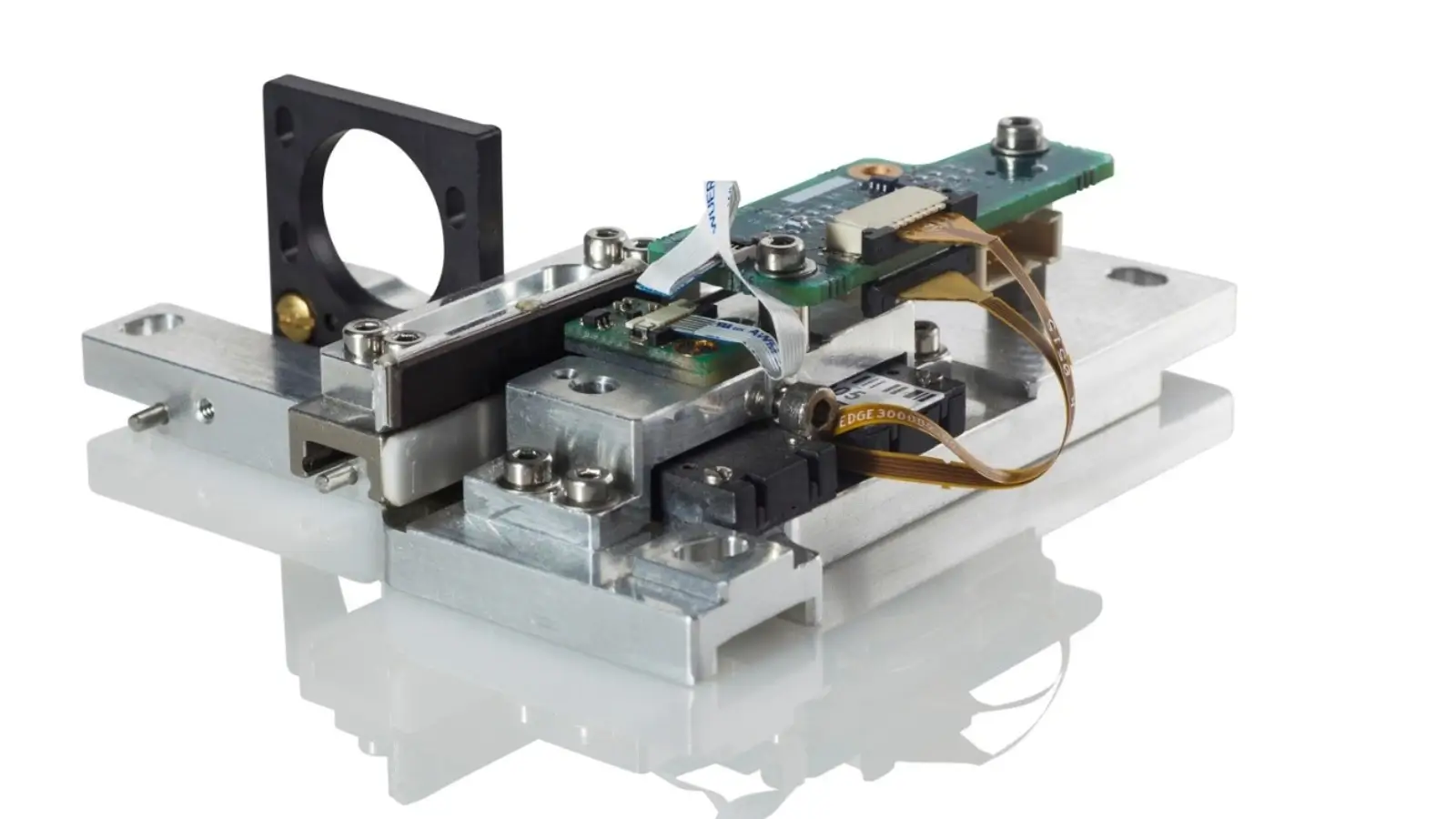

In high-end manufacturing or laboratory automation, motion systems coordinate multiple axes of movement, often requiring nanometer-level precision. They couple cutting-edge algorithms able of real-time adjustments with hardware including motors, drives, and encoders. Machines can execute intricate tasks like scanning, alignment, or microassembly without human involvement thanks to this integration.

The move toward smaller, more effective actuators is among the most intriguing advances in recent years. Although conventional electromagnetic motors are still quite common, new technologies are developing that beat them in certain uses.

Among these, Piezoelectric Motors have gained particular attention. Piezoelectric effect, a quality of some materials that produce movement when exposed to an electric field, powers them. Piezoelectric systems generate movement using vibrations at ultrasonic frequencies unlike conventional motors, which depend on magnetic fields and revolving components. This lets them get very exact positioning with practically no mechanical backlash.

Piezoelectric actuators are now indispensable in applications including aerospace, biomedical engineering, and semiconductor manufacturing because of their small size, quiet operating, and capacity to operate in a cleanroom or vacuum setting. Their adaptability also makes them perfect for uses where conventional motors cannot deliver the necessary accuracy or speed.

The merger of data analytics and AI-driven control is yet another upheaval transforming precision engineering. Smart sensors feed machine-learning algorithms data on position, force, and temperature among other characteristics. These technologies can automatically correct for environmental disruptions, forecast wear, and maximize trajectories.

Predictive maintenance and adaptive manufacturing especially benefit from artificial intelligence-powered motion control. Machines may automatically calibrate or adapt to material variations, lowering downtime and increasing yield. As more sectors embrace this approach, we get closer to entirely automated production lines whereby real-time optimization of accuracy is ongoing.

The influence of these inventions reaches far outside production. Precision actuators power prosthetics, surgical robotic systems, and diagnostic equipment in healthcare. In aerospace, under harsh circumstances they help optical alignment and satellite positioning. They give tactile feedback on touchscreens and improve image stabilization in cameras in even normal life.

The demand for accuracy, repeatability, and control—core values of modern engineering that keep developing with every technological advancement—ties all these applications together.

Notwithstanding great strides, problems still exist. Engineers have to control thermal effects, minimize energy use, and strike miniaturization against longevity. Sustainability is becoming a key design requirement as companies look for ecologically sensitive materials and production methods.

Future studies will probably concentrate on hybrid actuating systems that combine several technologies, including piezoelectric and electromagnetic components, to maximize performance under a range of circumstances. Furthermore perfecting accuracy and lowering development expenses will come from the incorporation of digital twins—virtual replicas of real systems.

The way motion is produced and controlled is being changed by the merging of mechanics, electronics, and artificial intelligence. Smart actuation systems keep pushing the envelope of accuracy, from tiny sensors to massive automation. Innovations in materials, design, and control will drive the following wave of engineering advancement as businesses call for greater performance and sustainability—making movement smarter, more effective, and more dependable than ever before.