A wire stripping machine is an essential tool for electrical contractors, manufacturing facilities, recycling operations, and any business that processes large volumes of cable. Choosing the right machine can dramatically improve efficiency, accuracy, and worker safety. With so many models on the market, it can be difficult to know which features truly matter. Understanding the capabilities that separate a dependable wire stripping machine from a mediocre one can help you make the best investment for your operation.

The first feature to evaluate is material compatibility. Not every wire stripping machine can handle the same range of cable insulation types, thicknesses, or materials. High-quality machines accommodate a wide variety of cable compositions, including PVC, rubber, nylon, Teflon, and fabric braid. Some advanced units can even process armored cable or coaxial lines. When choosing a machine, consider the types of wires your business handles most frequently. If you work in recycling or industrial environments, you need a machine versatile enough to strip everything from thin household electrical wires to thick industrial cables. A machine with limited compatibility may force additional manual labor or require separate equipment. The best machines are designed for flexibility so operators can switch between materials without causing downtime.

Precision is critical when stripping wire. The machine must remove insulation cleanly without damaging the conductor. Look for adjustable cutting depth controls and blade positioning features that allow operators to fine-tune the machine for different cable diameters. High-quality machines include clearly marked adjustments, straightforward calibration steps, and tools that allow for quick changes between settings. Inaccurate cutting depth can lead to conductor nicks, which compromise safety and performance. Precision also affects productivity since poorly adjusted machines slow down operators. Machines with well-engineered controls reduce the risk of errors and improve overall efficiency, making them essential for both high-volume operations and smaller shops that value consistent results.

A wire stripping machine is only as effective as its output. Throughput capacity determines how much wire the machine can handle in a given time. For businesses that deal with high cable volumes, choosing a machine with sufficient speed is essential. Motor power, feed mechanisms, and design efficiency all contribute to performance. Some machines can process hundreds of feet of wire per minute, while others are designed for slower but more precise work. Think about your daily workload. If your business strips wire continuously throughout the day, a high-speed wire stripping machine helps maximize production and reduce labor costs. If you only process small batches occasionally, speed may be less important than accuracy and ease of use.

Durability is one of the most important features to consider before purchasing a wire stripping machine. The machine should withstand constant operation without frequent repairs or component wear. Look for models constructed with heavy-duty metals, corrosion-resistant components, and industrial-grade motors. Solid build quality ensures the machine can handle the tension and pressure applied during the stripping process. A poorly built machine may work initially, but can develop mechanical issues within months. Machines with high-quality materials, reinforced gears, and long-lasting bearings not only operate more smoothly but also reduce downtime and long-term maintenance costs.

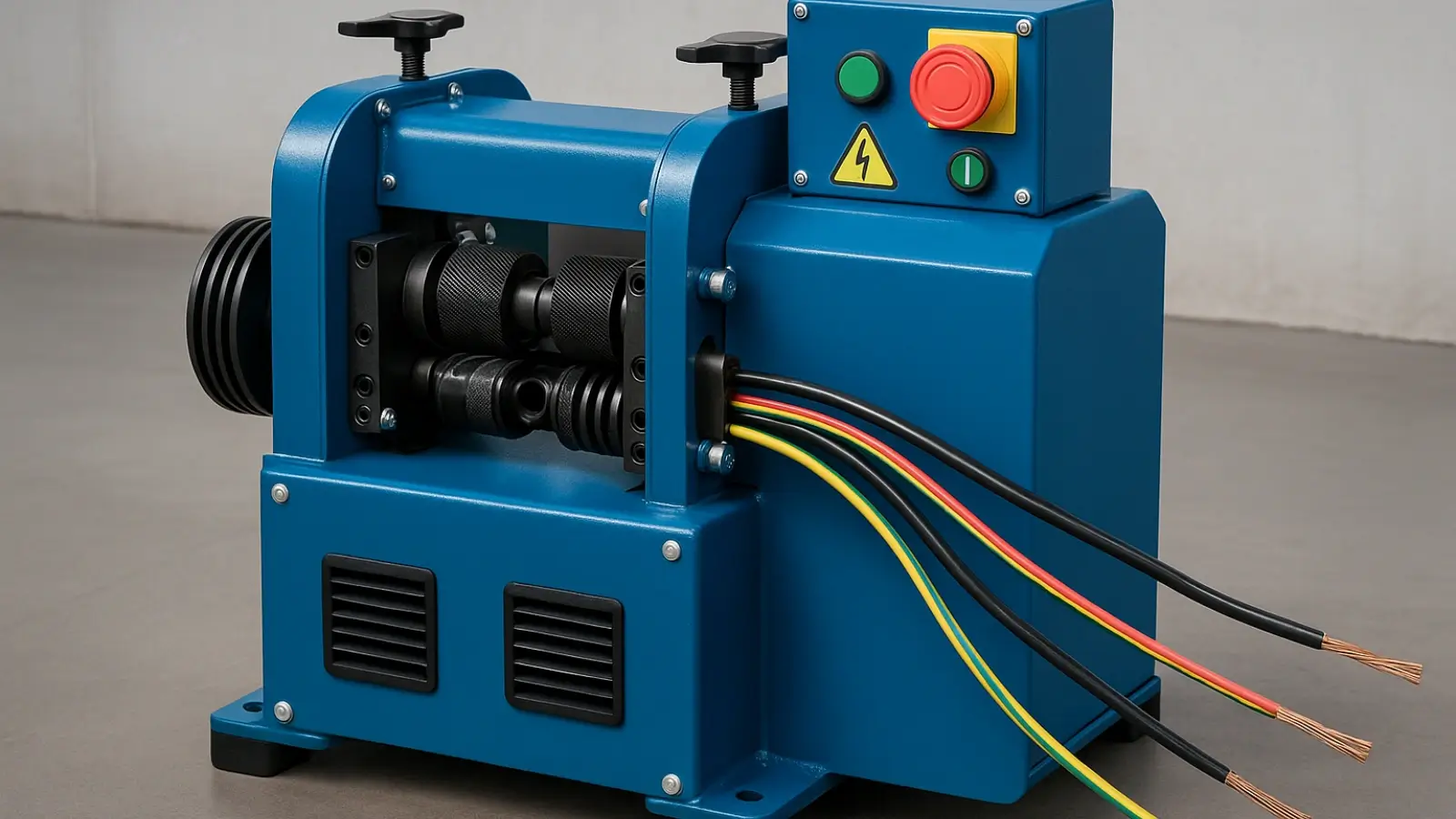

The blade system is the heart of any wire stripping machine. High-performance machines offer multiple blade types or interchangeable cutting tools to accommodate different wire sizes and insulation styles. Blades should be made from hardened steel or other premium materials that resist wear and maintain sharpness over time. Adjustable blade angles, automated blade positioning, and dual cutter setups can enhance performance and adaptability. If your operation processes a wide range of cables, a machine with versatile blade options is crucial. Investing in quality cutting components ensures the machine continues performing accurately even with heavy use.

Safety should always be a priority when choosing any industrial equipment. A wire stripping machine includes moving parts, cutting components, and feeding mechanisms that require proper safeguards. Look for features such as protective covers, emergency stop buttons, and automatic shutoff sensors. Machines with stable bases, anti-slip feet, and ergonomic feeding designs also help reduce workplace accidents. For higher speed or fully automated machines, safety interlocks prevent operation when guards are removed. A safe machine protects both your workforce and your business, reducing the risk of injuries and associated costs.

User-friendly operation is another essential feature, especially for teams with multiple operators. A machine with a clear control panel, intuitive instructions, and easy setup helps reduce training time. Simple loading mechanisms and smooth cable feeding systems make the machine easier to use and maintain steady productivity. Machines with poor operational design can frustrate workers and lead to avoidable mistakes. Clear labeling, accessible controls, and well-engineered layouts improve operator confidence and reduce downtime. Whether your business handles wire stripping daily or periodically, ease of use ensures smoother workflows and consistent output quality.

Routine maintenance is necessary for any machine, but the best wire stripping machines make this process simple. Consider how quickly you can clean the machine, access internal components, and replace blades or worn parts. Machines designed with accessibility in mind reduce the time and effort required for upkeep. Look for machines with removable panels, tool-free blade changes, and self-cleaning feeding tracks. Some advanced machines include lubrication ports or automated cleaning systems. A machine with minimal maintenance needs not only reduces downtime but also extends the life of the equipment.

The physical footprint of a wire stripping machine matters, especially for small workshops or mobile operations. Compact machines save space and can be mounted on workbenches or transported between job sites. Larger industrial models provide higher speed and capacity but require more dedicated space. Consider how the machine will fit into your workflow. If mobility is important, choose a machine with handles, wheels, or lightweight construction that still maintains durability. For stationary operations, focus on performance rather than portability.

As industries shift toward automation, many wire stripping machines now include semi-automatic or fully automated features. Automated wire feeding, programmable cutting cycles, and digital controls allow for faster, more accurate processing with minimal manual intervention. Some advanced models include LCD displays for setting wire length, cutting depth, and batch quantities. Automation reduces human error, increases throughput, and improves consistency. If your business handles repetitive stripping tasks, investing in automation can significantly enhance efficiency.

Energy consumption is often overlooked, but it plays a major role in operational cost over time. Efficient motors, automated controls, and modern engineering help reduce electricity use without sacrificing performance. Machines designed with energy efficiency in mind run cooler, last longer, and cost less to operate. For high-volume facilities, this can translate to substantial savings.

A reliable warranty and accessible customer support offer peace of mind. Quality manufacturers stand behind their machines with comprehensive warranties that cover essential components. Responsive technical support, available replacement parts, and repair resources help maintain productivity and reduce downtime. Before choosing a machine, research the manufacturer’s reputation and long-term support options. A lower-cost machine without dependable support can become more expensive in the long run.

A wire stripping machine is a valuable asset for any business that handles electrical cable. By focusing on features such as material compatibility, precision controls, speed, durability, safety, and automation, you can choose a machine that boosts productivity and supports long-term operational success. Taking the time to evaluate these key features helps ensure your investment performs reliably and delivers consistent results for years to come.